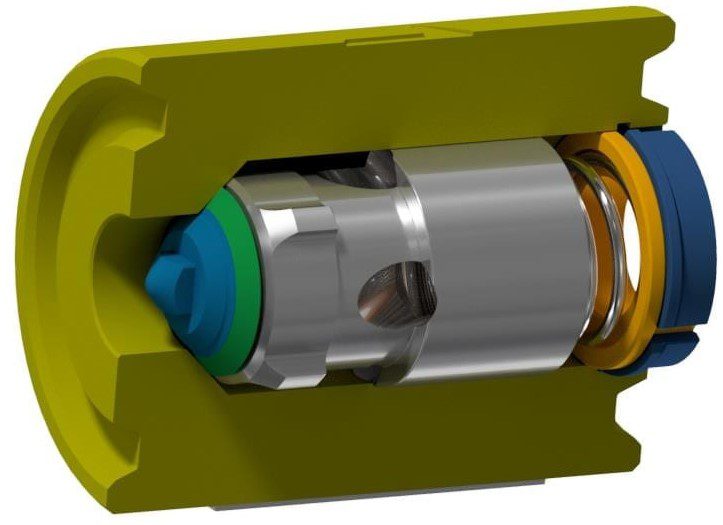

Check Valves provide full metal to metal sealing (combined metal to metal and polymeric) across a wide range of temperatures.

Check Valves are used within fluid control system to perform a vital function by preventing reverse flow of fluid that increases efficiency of operation sand negates the potential for damage to the fluid control system.

The Check Valve, effectively a non-return valve, can be installed as a standalone unit or built integrally into the inlet or outlet of a Rotary gate valve or Through Conduit Split gate valve. There are various designs of Check Valve which is dependent on the application, with the standalone design coming in varying shapes – the bean can, the top hat and the rolling pin.

The flexibility of the core Bentley check valve design offers many alternatives including threaded, butt weld, flange mounted and ‘sandwich’ options to fully satisfy the bespoke customer requirements.

The spool-to-body primary seal is metal-to-metal with a PTFE secondary seal. Lift pressures can be customer specified – typically 1 to 4 bar which support the pressure requirements of the fluid control system.

Recognising that soft-faced Check Valves are susceptible to contamination, field servicing of the valve by simple replacement of the spool assembly has been designed to be as simple a process as possible. Crucially, installation in a gate valve assembly is carried out without affecting the integrity of any seat to body interface, which is a major issue for other design solutions.

½” and 1” nominal bore size

Compact design

Primary metal sealing

Secondary sealing

Integral or standalone

FF and HH trims

Qualification:

Qualified to a pressure rating of 15,000psi

3,048m (10,000ft) water depth

Qualified in accordance with API 6A 20th edition and API 17D 2nd edition

Temperature range: -29°C to 150°C

LB Bentley design and manufacture bespoke small bore subsea valves for chemical injection applications on XMT’s and manifolds in subsea systems.

With 35 years of field proven success our valves are known for their reliability and compact design, LB Bentley’s innovative approach enables us to qualify our valve to suit customers’ specification requirements and fully satisfy API 6A and 17D standards as a minimum.

LB Bentley pioneered metal-to-metal sealing technology with our Through Conduit Gate Valves, Rotary Gate Valves and Check Valves, enabling us to reduce the risk of contamination and failure and deliver truly flexible, robust and reliable products.

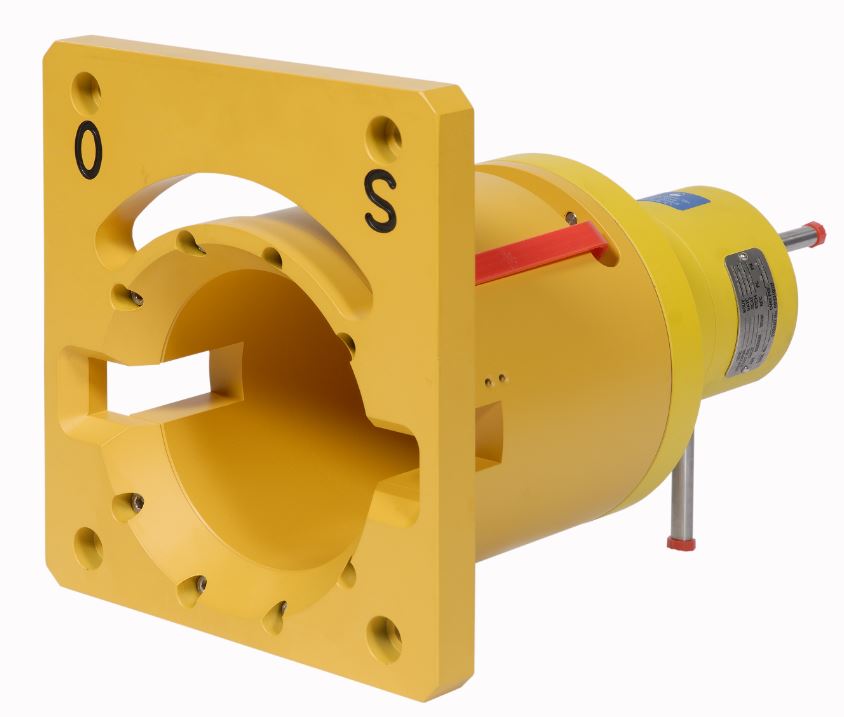

Based on a design with field proven success: the Medium Duty Rotary (MDR) valve delivers a more reliable and cost-effective solution to other valves in the targeted applications.

With the seat and gate technology taken directly from our successful and field proven rotary gate valve design, our Medium Duty Rotary (MDR) Gate Valve is designed for specific applications where a more standardised and economic product is required.

The MDR delivers the same reliability and performance as our field proven rotary gate valve design with the economic benefit of a simplified design, whilst fully satisfying the requirements of API 6A and 17D.

The valve has been designed with panel mounted applications in mind, including hydraulic control and test lines on XMTs, manifold panels and subsea distribution units where needle and ball valve products are conventionally used – but where a metal sealing gate valve provides increased reliability to suit the customers’ needs, without the need for additional expense.

½” nominal bore size

Compact design

Metal to metal gate to seat

FF trim

Dual stem seal

ROV interface

Qualification:

Qualified to a pressure rating of 15,000psi

3,048m (10,000ft) water depth

Qualified in accordance with API 6A 20th edition and API 17D 2nd edition

Temperature range: -29°C to 82°C

LB Bentley design and manufacture bespoke small bore subsea valves for chemical injection applications on XMT’s and manifolds in subsea systems.

With 35 years of field proven success our valves are known for their reliability and compact design, LB Bentley’s innovative approach enables us to qualify our valve to suit customers’ specification requirements and fully satisfy API 6A and 17D standards as a minimum.

LB Bentley pioneered metal-to-metal sealing technology with our Through Conduit Gate Valves, Rotary Gate Valves and Check Valves, enabling us to reduce the risk of contamination and failure and deliver truly flexible, robust and reliable products.

The Rotary gate valve embrace innovative design: using metal to metal sealing technology delivering a reliable, efficient and compact solution.

Our Rotary Gate Valve has minimal moving parts, the quarter-turn mechanism delivers a wipe-clean action ensuring that the valve performs reliably even with the dirtiest of fluids. This self-cleaning ‘wiping’ action between the gate and buttons, plus the use of metal to metal sealing technology, ensures the integrity of the valve and further promotes the longevity of its performance in the subsea field.

The Rotary Gate Valve can be operated manually with an ROV interface or hydraulically with our patented OPTItorkTM actuator with a manual over-ride if specified. Valve is also truly flexible with the option to be either panel or block mounted to satisfy the customers XMT design.

Being designed with space saving simplicity in mind the Rotary Gate Valve satisfies the demands of the industry in supporting the drive to reduce the size of XMT’s and manifolds.

Robust and simple, our Rotary Gate Valves suit many applications and various media – from hydraulic fluids to well fluids to injection chemicals. It is compact and light weight making it perfect for use in small space envelopes and its versatility means that it can be used in any orientation, with flexible porting and mounting capabilities to suit any customers’ needs.

3/8” to 1” nominal bore size

90° operation (open & close)

Compact design

Metal to metal gate to seat

Self-wiping action

Bi-directional

FF and HH trims

Manual or hydraulically actuated

Qualification:

Qualified to a pressure rating of up to 15,000psi

3,048m (10,000ft) water depth

Qualified in accordance with API 6A 20th edition and API 17D 2nd edition

Temperature range: -29°C to 150°C

LB Bentley design and manufacture bespoke small bore subsea valves for chemical injection applications on XMT’s and manifolds in subsea systems.

With 35 years of field proven success our valves are known for their reliability and compact design, LB Bentley’s innovative approach enables us to qualify our valve to suit customers’ specification requirements and fully satisfy API 6A and 17D standards as a minimum.

LB Bentley pioneered metal-to-metal sealing technology with our Through Conduit Gate Valves, Rotary Gate Valves and Check Valves, enabling us to reduce the risk of contamination and failure and deliver truly flexible, robust and reliable products.

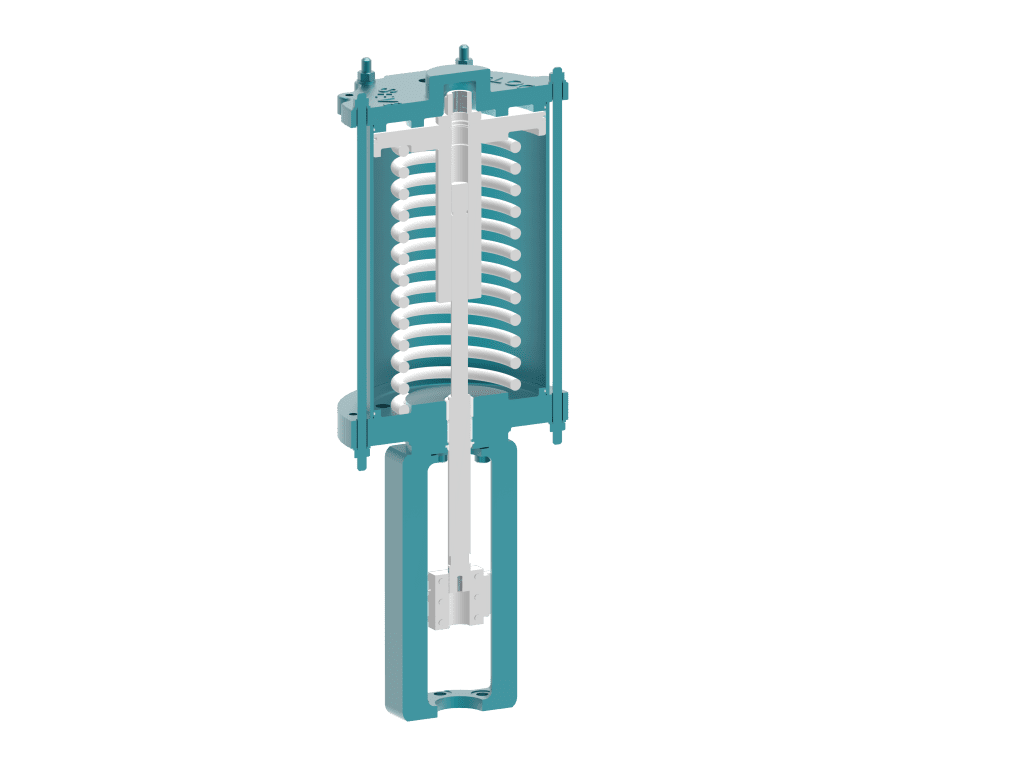

Almost 35 years of reliable field-proven success: The first small bore subsea valve to go subsea.

The unique design of the Through Conduit Split Gate valve, with full metal to metal sealing throughout the flow bore giving a true metal to metal seal between the seat and body, delivers a reliable performance that can tolerate contaminated and dirt laden fluids which makes other valve designs vulnerable, significantly reducing the risk of failure.

With our patented static leaf spring design the split gates are pre-loaded against the seat face giving a perfect seal. By pre-loading the gates at the centre line of the seat ensures that the seat/gate contact is always maintained, this achieves a low pressure gas tight seal without the aid of lubricant or sealant injection.

The flexibility of this design for the Through Conduit Split Gate valve allows Bentley to deliver a bespoke solution that satisfies the customers’ needs and has the ability to optimise performance in any given application.

½” and 1” nominal bore size

Compact design

Metal to metal seal seat to body

Metal to metal seal gate to seat

FF and HH trims

Mounted or remote

Manual or hydraulically actuated

Integral metal to metal check valve available

Qualification:

Qualified to a pressure rating of up to 15,000psi

3,048m (10,000ft) water depth

Qualified in accordance with API 6A 20th edition and API 17D 2nd edition

Temperature range: -29°C to 150°C

LB Bentley design and manufacture bespoke small bore subsea valves for chemical injection applications on XMT’s and manifolds in subsea systems.

With 35 years of field proven success our valves are known for their reliability and compact design, LB Bentley’s innovative approach enables us to qualify our valve to suit customers’ specification requirements and fully satisfy API 6A and 17D standards as a minimum.

LB Bentley pioneered metal-to-metal sealing technology with our Through Conduit Gate Valves, Rotary Gate Valves and Check Valves, enabling us to reduce the risk of contamination and failure and deliver truly flexible, robust and reliable products.

Ancillary & Bespoke equipment: Individual items or integrated accessories that broaden our service proposition.

To further support our customers’ needs Bentley offer a range of ancillary & bespoke equipment solutions that includes actuator mounted compensators, extension rods, ROV buckets and positioners. It also features the integration of valves into a specified manifold arrangement and the fitting of electronic sensors and specialised testing/qualification.

Stem Extensions: Where the design of the customers XMT demands the need to overcome space envelope challenges we can help achieve their requirements. For example, where the small bore subsea valve is required to be placed deep within the XMT due to these space challenges, LB Bentley can design and build bespoke stem extensions that still enable ROV access to operate the valve in such a position, without compromising the reliability of the valve operations. This can all be achieved whilst ensuring the correct positions of earth straps, the consistency in electrical continuity and that the position of the valve is being correctly shown by means of a directly linked indicator.

Compensators: Where necessary, we can provide purpose-designed hydraulic compensators. They connect directly to the actuators without the need for external pipework, providing a piston displacement function if a sea chest is not available, ensuring the integrity of the valve in deep water.

ROV (Remove Operated Vehicle) Receptacle/Buckets: Where the valve is panel mounted or is operated by means of a stem extension ROV receptacles can be supplied in all the usual interfaces, for example, ISO 13628-8 Class 2, 3 and 4, High Torque/Low Torque or interfaces personalised to customers’ requirements or specifications. The ROV receptacles may be mounted to the valve, the actuator or the panel at the end of a stem extension, they may also be supplied as a stand-alone unit.

LB Bentley design and manufacture bespoke small bore subsea valves for chemical injection applications on XMT’s and manifolds in subsea systems.

With 35 years of field proven success our valves are known for their reliability and compact design, LB Bentley’s innovative approach enables us to qualify our valve to suit customers’ specification requirements and fully satisfy API 6A and 17D standards as a minimum.

LB Bentley pioneered metal-to-metal sealing technology with our Through Conduit Gate Valves, Rotary Gate Valves and Check Valves, enabling us to reduce the risk of contamination and failure and deliver truly flexible, robust and reliable products.

Designed for fitting onto a wide range of Control valves, louvres or dampers, these high power actuating units are for use in on/off, or modulating service with increased thrust capacity compared to diaphragm actuators.

Available as either a single acting or double acting unit. The design is field reversible and utilises a wide range of springs to provide positive fail action. Positioners are normally yoke mounted and of the double-acting type providing air to both sides of the piston and giving a robust and precise unit that is resistant to load fluctuations.

Design Features:

- High thrust capability, capable of using air supplies up to 150psig (10bar)

- Multi-size options with long stroke capability

- Robust components for trouble-free, low-cost ownership

- Positive spring air fail action, which is not field reversible

- Lightweight corrosion resistant construction

- Rotary options available

Benefits

- High degree of stem positioning accuracy

- Cylinder design has lower air consumption than a comparable diaphragm actuator

- Highly stable providing inherent stiffness over full stroke

- Highly responsive with minimum latency on movement or positioning

- High resolution of stem positioning for up to 12in strokes as standard with longer strokes available

- Adjustable actuating forces to suit different applications

- Rigorous in-field testing

- Manufactured to ISO 9001 certification

To find out more about the P-Series Actuator, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Actuator based enquiry, you can contact the Severn team by completing the enquiry form located here.

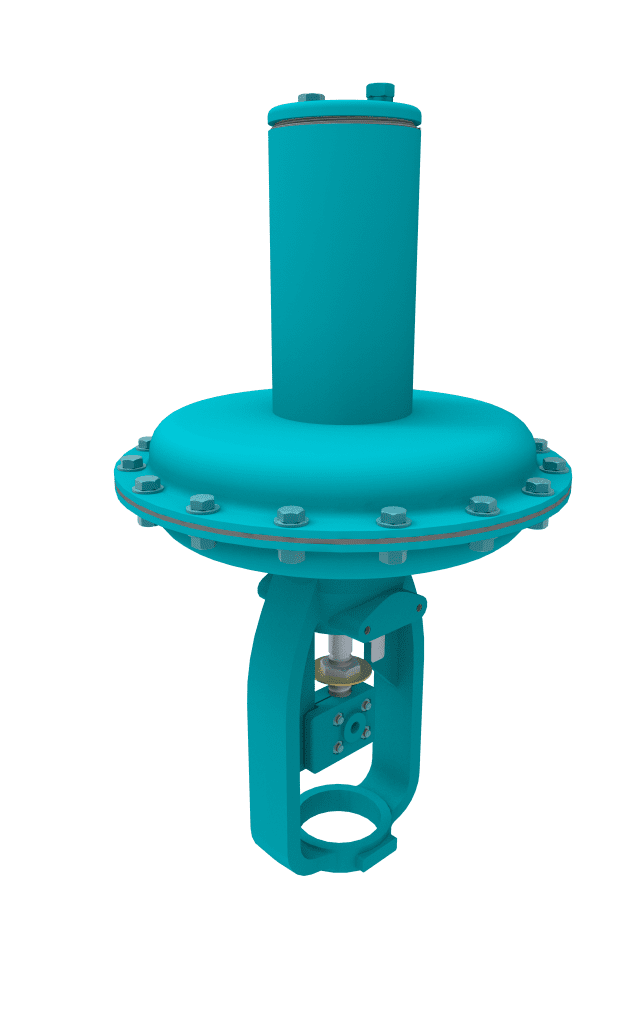

The W-Series Pneumatically Operated Spring & Diaphragm Actuator is designed to satisfy the majority of general Control valve applications.

With proven reliability, even in the most adverse climate conditions and temperatures, the range compromises three basic actuator sizes which, when combined with different spring ranges, provide a travel capability of up to 3 1/2 (89mm). The spring air fail action delivers crucial reliability for critical applications and a pre-compressed bench set is available across the range of fitted springs.

Design Features:

- High power, fast response

- Operates from low-pressure air supply

- Low-stressed, positive spring fail action in either air fail open or close orientation

- Field reversible to change fail safe position

- Steel construction with minimal parts for low-cost, trouble-free operation and maintenance

- The assembly is bolted to a cast yoke combining lightness with mechanical strength

Benefits

- Proven, reliable, low-cost performance

- Fire-resistant construction, with positive fail position

- Adjustable pre-compressed spring forces

- High degree of reliability with low hysteresis

To find out more about the W-Series Actuator, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Actuator based enquiry, you can contact the Severn team by completing the enquiry form located here.