Extra-Long Stem Extensions Overcome XMT Space Constraint

The challenge

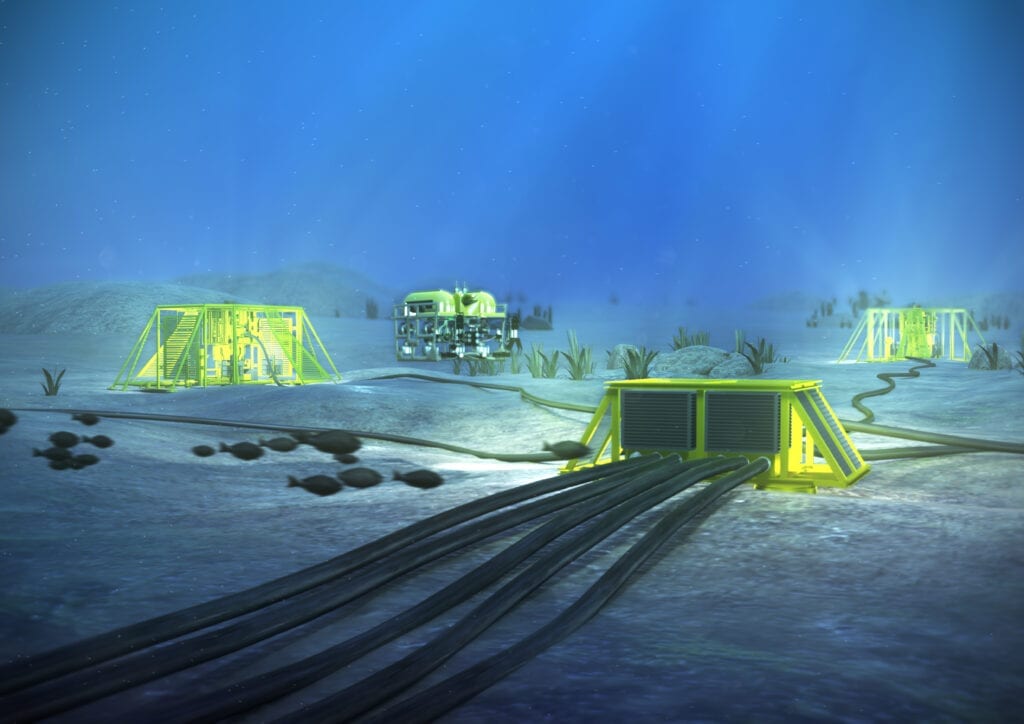

The brief was to design and manufacture small bore subsea valves occupying positions deep within an XMT structure, due to space and location restrictions. They required stem extensions ranging from 1m to 6.3m so they could be controlled by a Remote Operated Vehicle (ROV) outside the structure.

These were the longest stem extensions ever supplied by Bentley. Their design and manufacture involved significant technical considerations surrounding material specification and interface design.

The solution

Bentley’s engineering department used a blend of existing design modification and radical design to develop an effective solution.

Material specification

This demanded particular attention, including detailed assessment of tensile strength. The extensions needed to be robust and non-flexing, but not brittle. Ultimately, mild steel was the material of choice for the stem extensions on this project.

Valve adaptations

Existing valve design needed to be reconsidered to accommodate the longer stems. For instance, indicator rods usually move rotationally, but due to the stem length required in this project the design was modified to accommodate a linear moving indicator rod. The linear design was ultimately used for all of the valves provided by Bentley for this contract, irrespective of stem length. Interface design The indicator needed to give a true open/ shut reading for the valves.

Additional features

With the introduction of a sheer point in to the design this enables the valve to remain fully operational even if the indicator rod became inoperable. In assembly the sheer pins were designed to be an interference fit, therefore they needed to have an angle on the sides to allow for a small for partial insertion to ease assembly. There also need to be additional guides added to the bucket end to ensure that all rotational movement was eliminated.

Bentley worked in partnership with the operator throughout the design, assembly and testing of the valves. Due to the extreme design challenges functional tests were conducted on the full assemble before valves left the factory. This provided assurance that the set-up was fully functional before the valves were added to the XMT.

The outcome

Bentley successfully developed and tested the extra-long stem extensions, enabling the customer to overcome significant challenges surrounding XMT space envelopes. This is a landmark niche development for subsea operations. Space constraints are set to become a critical future design issue as XMTs become increasingly compact. Further developments currently being explored by Bentley include the use of stainless steel for all stem extensions, as opposed to mild steel, this will eliminate the need for the application of rust proof preventative in the future.

This is a landmark niche development for subsea operations If you want to read more of our case studies, you can find them by clicking the Case Studies button below or if you would like to contact us with an application, engineering or other valve query than click the contact us button. Alternatively, you can download the full stage case study via the download button below.