With over 60 years’ experience in the design and manufacture of Butterfly Valves, Severn launches a range built on decades of learnings and innovative engineering.

In the dynamic landscape of industrial engineering, innovation often stems from a rich heritage of expertise and an unyielding commitment to excellence. Severn Glocon, a renowned name in the world of valve design and manufacturing, have once again proven this statement true with the unveiling of the superior Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve. This development represents Severn’s commitment to innovation in the realm of process and industrial energy markets, promising enhanced performance, reliability, and efficiency.

Engineering Heritage: The Foundation of Excellence

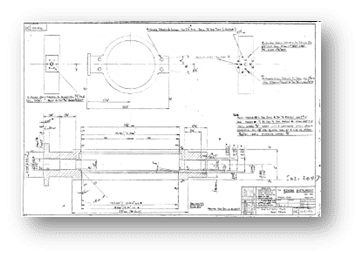

Severn’s journey to engineering eminence is woven with a tapestry of innovation and dedication stemming back over 60 years. With an engineering history extending back to 1957 and the design and manufacturing of Globe Control Valves, Severn has continuously pushed the boundaries of valve technology and design, earning a reputation for precision engineering and unmatched quality. Drawing from this extensive engineering heritage, Severn has consistently delivered solutions that exceed industry standards and address the evolving needs of diverse sectors.

Unveiling the Oblique Cone Technology (OCT)

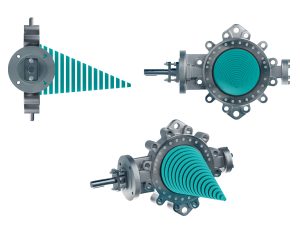

At the heart of Severn’s latest engineering triumph lies the OCT TOV Butterfly valve, a revolutionary advancement in Butterfly valve design and performance. Unlike traditional Butterfly valves, which often suffer from limitations in sealing performance and durability, the OCT TOV Butterfly Valve introduces circular sealing geometry.

Unlike traditional triple offset designs that use an ellipse. The benefit of circular geometry is that it provides a uniform sealing load around the circumference of the sealing diameter, providing a reliable and repeatable shut-off. By using circles rather than ellipses, it allows Severn to use proven circular sealing knowledge and incorporate this into the TOV.

Incorporating Severn’s ‘Repair Intelligence’ knowledge which involves providing real market feedback from extensive in-depth analysis from failed valves. Severn have designed each facet of this valve to provide the most accurate, reliable, and robust service capability possible whether managing critical processes in Oil & Gas refineries, Chemical Plants, or Power Generation facilities, the OCT TOV Butterfly valve ensures the end user achieves their core remit of safe operations and minimum downtime.

Advantages for Process and Industrial Energy Markets

The introduction of the innovative OCT TOV Butterfly Valve designed by Severn signifies a paradigm shift in valve technology, offering a host of benefits to the Process & Industrial Energy markets

Enhanced Performance: Severn have designed each facet of this valve to provide the most accurate, reliable, and robust service capability possible to help the end user achieve their core remit of safe operations and minimum downtime.

Extended Lifecycle: Process conditions can change with time. Severn have ensured the interchangeability of the seal, should the sealing requirement not become as critical, or process conditions become more arduous.

Increased Safety: At Severn, safety is paramount to the design of our products and ensured that whilst adhering to the strictest industry standards, have incorporated shaft blowout prevention as a vital addition to the design of the valve to increase suitability for end users and the wider industry.

Versatility: Utilising Severn’s extended history of engineering excellence, the OCT TOV Butterfly valve has been designed for both superior control in both throttling and modulating services, whilst additionally providing a repeatable seal for isolation duties.

Environmental Sustainability: To further the commitment to reducing fugitive emissions and reduce the burden on end users to meet tightening specifications, all Severn’s OCT triple offset butterfly range offer the fugitive emissions packing sets as standard fitment on all standard valves in the range.

Severn’s relentless pursuit of engineering excellence has culminated in the development of the OCT Triple Offset Butterfly Valve – a testament to the company’s unwavering commitment to innovation and customer satisfaction. As industries worldwide seek ever-improving solutions to their operational challenges, Severn Glocon stands ready to lead the way, setting new benchmarks for performance, reliability, and efficiency in valve technology.

Compressor anti-surge control valves for FPSO North Sea Client delivered three days ahead of schedule

Compressor anti-surge control valves for FPSO North Sea Client delivered three days ahead of schedule

Compressor Anti-surge Control Valves delivered three days ahead of schedule

Industry : Oil & Gas FPSO

Location: UK Central North Sea

Project: Two anti-surge control valves to be delivered within a tight time frame for UK Central North Sea Client

The Challenge:

A North Sea operator needed a solution for a technically challenging anti-surge application, required on a very short delivery schedule of 16 weeks, the initial requirement was for one valve to be delivered and the second valve to be delivered 10 days later.

Finding a solution:

The Severn team made initial engagement with the client to full understand the application and performance requirements that the customer needed.

A swift coordinated approach internally by Severn’s application and engineering team was needed and the teams worked closely together as it was imperative that the issue was identified quickly so a solution could be provided, manufactured and delivered within the 16-week delivery schedule.

The product:

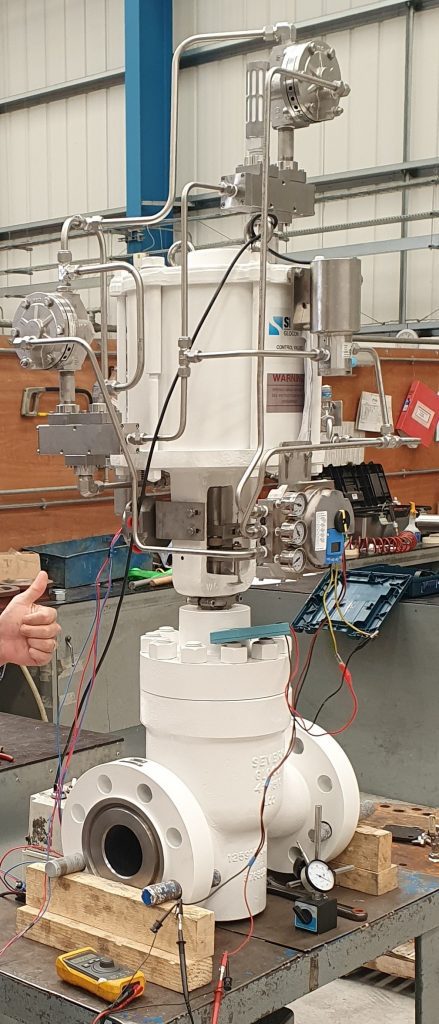

After identifying the clients requirements, the engineering team designed and manufactured two off 4” Cass 1500 RTJ Fig 5413 LTCS Body, SS/FC Trim, 14 Turn CCD, PC1N Pneumatic actuator with a Neles Positioner.

The positioner was revised mid order as per clients added operational requirements, the team was seamless in reacting to this change with no impact on the design or delivery schedule.

The outcome:

The contracts department managed the scope of the job and the challenges it brought professionally and with complete transparency; the client was kept fully informed throughout the production and delivery process.

The collaboration between the different departments and the constant engagement and the feedback with the client ultimately led to both valves being delivered three days in advance of the 16-week schedule, this was appreciated by the client.

The valve performed significantly well within the anti-surge required by the client for this application, especially on small step changes. This was a major issue with the clients previous valve, and an issue our team overcame with flying colours.

Severn requested to provide engineering support offshore on the asset, firstly with the installation and then subsequent valve commissioning activity.

” I want to take this opportunity to personally thank the entire Severn team for their continued focus and support during this project and more importantly, for getting both valves ready for shipping ahead of an already tight schedule.

Getting two high spec anti surge valves designed, assembled , and fully tested in less than 16 weeks is definitely an achievement” – Client representative

Severn Celebrates 21 years in Aberdeen.

Advanced valve engineering capabilities underpin success in the gruelling offshore oil and gas environment of the North Sea.

Enhancing the performance of existing offshore platforms has been a priority for North Sea oil and gas operators over the past two decades. With production steadily declining, finding ways to improve efficiency has been critical.

During this time, Severn has played an important role supporting leading operators with valve management and maintenance services as well as highly-engineered valve products. Longstanding client relationships are a defining feature of Severn’s business.

In 2010, Severn opened a dedicated Aberdeen facility to work in tandem with its established plant operations based then in Huddersfield and now in Brighouse. At the time, the Aberdeen team focused on the supply of traded isolation valves for North Sea operators. Today, the team works in close alignment with Brighouse under the direction of Managing Director David Brennan, as Severn’s hub for North Sea valve supply, servicing, testing and management and now Severn celebrates 21 years in Aberdeen, we are looking forward to the next years of growth and success.

Severn manufactures and supports high quality valves for the energy industries. Its control, choke and small bore subsea valves are pre-eminent in the global market, underpinning the reliability and high performance of business-critical client infrastructure.

Severn’s global reach, technical prowess, and collaborative approach – all founded upon a heritage of British engineering excellence – help to assure production continuity for clients and reduce the prospect of costly downtime.

Its understanding of the life-cycle of assets positions Severn to offer end-to-end engineering solutions, enabling clients to meet their core imperatives: safe operations and minimum downtime.