Discover how engineering excellence and heritage has driven Severn’s OCT TOV Butterfly Valve to deliver unmatched reliability in Seawater environments.

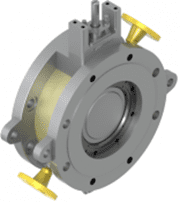

Severn’s research & development team has designed a Butterfly Valve that solves the problem of galvanic corrosion and meets strict fire test standards. Utilising the over 60 years of engineering excellence, the team of technical experts achieved this by using Severn’s patented Oblique Cone Technology (OCT). The OCT-SW takes this patented technology to the next level by eliminating the need for graphite in the seal and maintaining firesafe capability.

What is galvanic corrosion and its costly effects?

The impact of galvanic corrosion on critical assets due to seawater process conditions is an enduring problem for offshore oilfields. At best, it increases the workload and repairs associated with planned shutdowns. At worst it can result in rapid or unexpected damage, leading to unplanned or emergency shutdowns. Either way, it is a costly problem which harms efficiency, putting additional pressure on plant operating costs. However, Severn have utilised their engineering heritage, research and development & repair intelligence knowledge to develop a valve that deals with the issue of galvanic corrosion head on.

Why does galvanic corrosion occur? The cause of galvanic corrosion (also referred to as ‘dissimilar metal’ or ‘bimetallic’ corrosion) is an electrochemical reaction between two different conductive materials in close proximity. It results in one – the least noble of the two – being preferentially corroded. To combat this risk, the general rule is ‘do not mix metals’. However, when it comes to the design and development of assets for harsh offshore environments, things are rarely that straightforward.

Modern critical safety systems used on offshore sites are often highly sophisticated

to cope with the extreme natural conditions and industrial challenges with which they must contend. They come with extreme technical demands but must manage physical ones too; systems that need to feed water to combat fires must be durable enough to cope with the corrosive effects of the sea. Seawater service valves play an integral role in the process and their ability to either supply or isolate sections of the water line is a vital safety feature. Therefore, eliminating galvanic corrosion while maintaining firesafe credentials has been an enduring challenge for the industry.

In recent years, the use of graphite sealing technology has surged. Graphite’s extreme range of properties and characteristics makes it an ideal material in many ways. It is soft, flexible, and easy to cut, but it has high heat resistance and is almost inert. However, it is also the only non-metal that can conduct electricity. Furthermore, its nobility exceeds that of noble metals including stainless steel, bronze, and titanium. Yet it is often paired with these materials in valve manufacture, in the form of seals, packings and gaskets. From a galvanic corrosion perspective, graphite has become not only the solution to problems but can often be the cause.

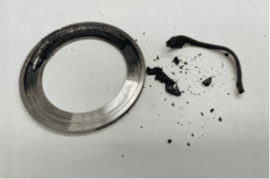

Traditionally, Triple Offset Butterfly Valves have used graphite materials in their construction, which can cause galvanic corrosion in seawater applications. This is a problem because it can significantly reduce the effectiveness of the valve’s sealing components, compromising safety and leading to potential costly unplanned downtime.

By working closely with end users and operators, Severn has recognized this issue, and with its significant engineering heritage and technical expertise, has designed a long-term solution. The Severn team of engineering experts designed a valve that either replaces the graphite components completely or stops them from contacting the line media. This significantly reduces the risk of galvanic corrosion in day-to-day operations and ensures the highest level of safety. Ensuring you achieve safe operations and minimal downtime.

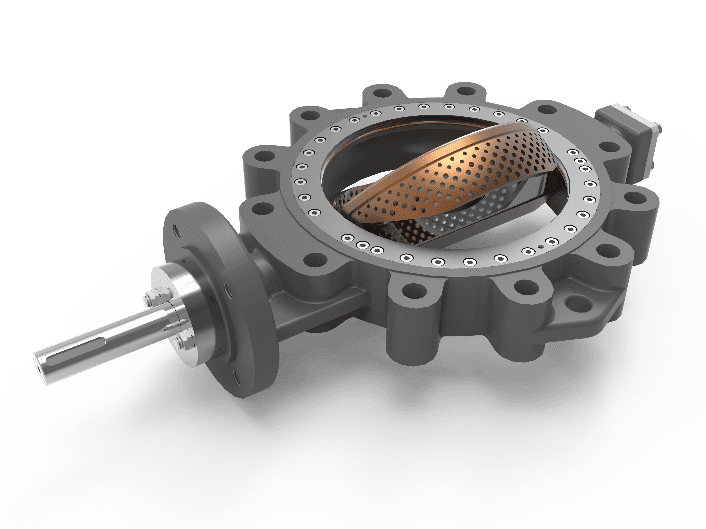

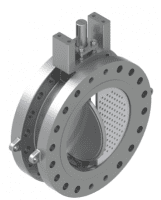

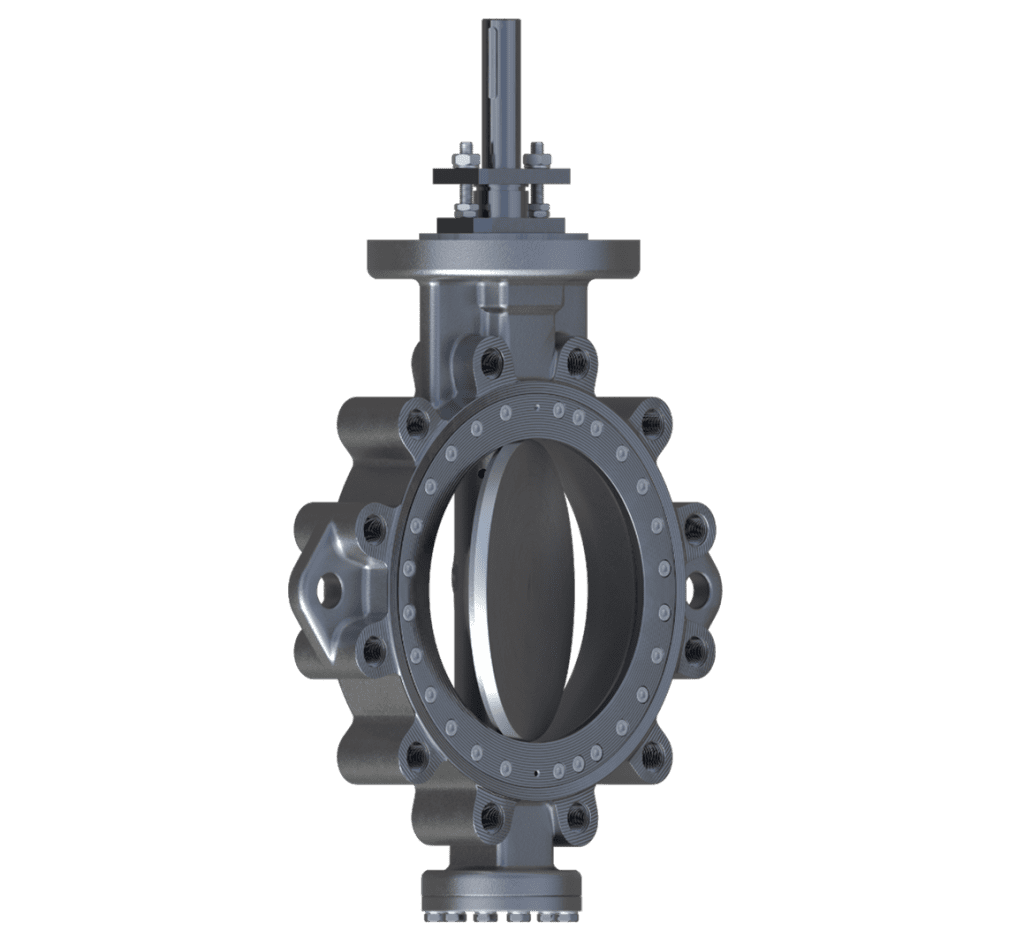

The Oblique Cone Technology (OCT) Seawater (SW) Triple Offset (TOV) Butterfly valve is a revolutionary type of valve designed primarily for use in saline applications, such as offshore oil and gas operations. These valves play a pivotal part in safety systems, as they play a crucial role in firewater systems. Due to Severn’s engineering heritage and technical expertise in the oil and gas operations sector, this valve has been designed with over 60 years of engineering excellence ensuring it helps the end user achieve their core remit of safe operations and minimum downtime.

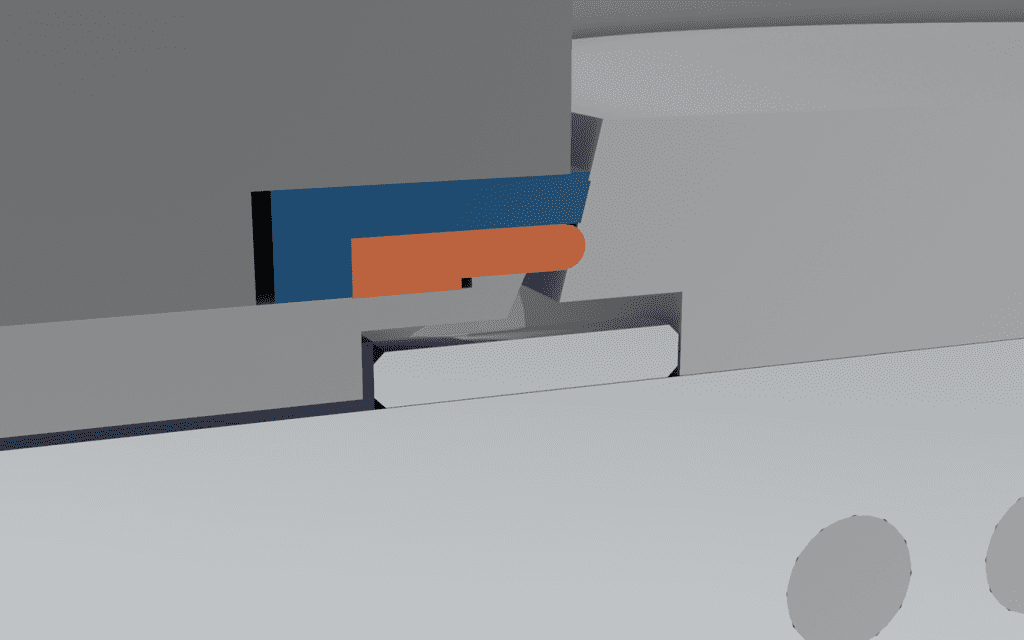

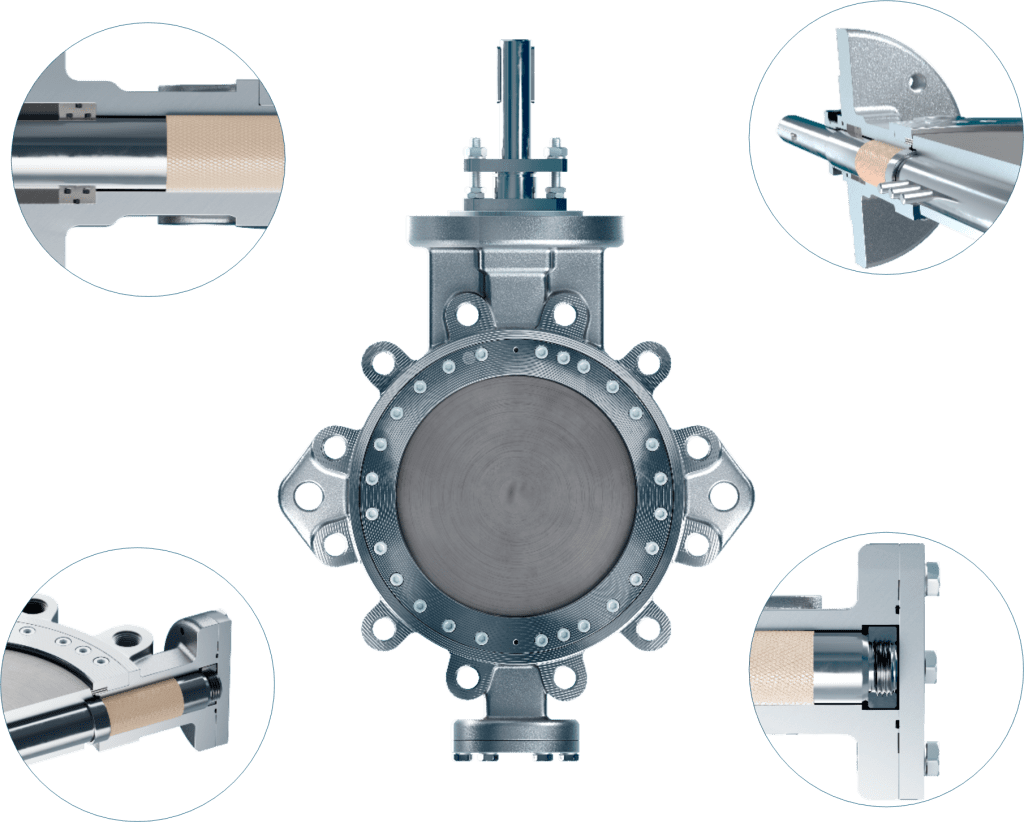

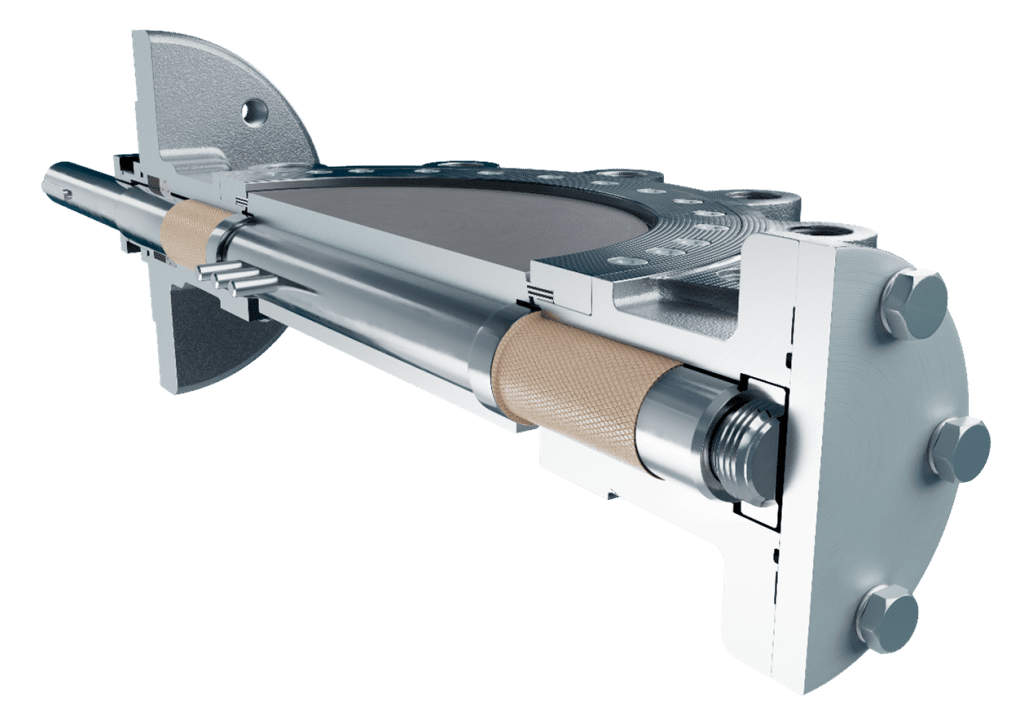

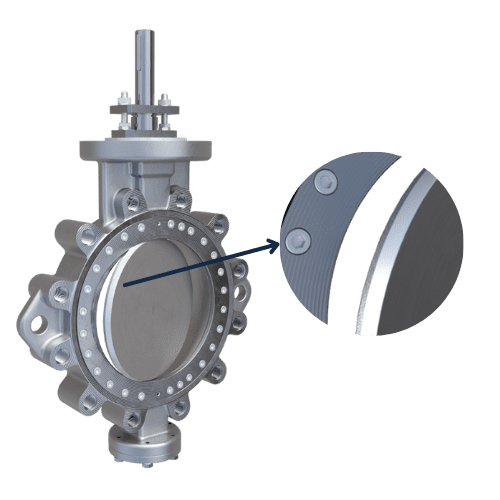

Severn has developed a hybrid polymer metallic seal that moves away from the use of graphite laminates. By utilising a primary metallic seal with a secondary polymer seal, not only have Seven removed the graphite from the seal but have additionally increased the valves isolation sealing capabilities and maintained the firesafe performance crucial for such critical applications. This coupled with isolating any graphite gaskets and packings from encountering the line media means that at no point during the normal operation of the valve do the graphite and seawater mix, eliminating the risk of galvanic corrosion and the costly effects it can have on production.

In addition to addressing the corrosion problem, Severn’s Butterfly Valves also meet important fire test standards such as API 6FA, API 607, and ISO 10497 accreditations. As such the OCT Valve is certified fire-safe and can be relied upon in critical emergencies for the end user and operators, ensuring safe operations and minimal downtime.

The team also took steps to ensure the valve design could not generate a spark and risk starting a fire itself. They followed the ISO/IEC 80079-36:2018 ATEX standard and ensured that no static charge could build within the valve. This additional element of care renders the new OCT-SW valve design suitable for a wide range of applications, beyond seawater service further emphasising the versatility of the valve design.

The OCT-SW can be manufactured from corrosion-resistant materials such as Aluminium Bronze, Super Duplex, and Titanium, with the added knowledge that anti-blowout protection comes as standard. Available in standard and non-standard face to face dimensions and various body styles such as lugged and double flanged, the valve can be easily retrofitted into existing pipeline spaces and is an ideal upgrade when operators are experiencing issues with galvanic corrosion.

Severn understands the ongoing challenges operators face with reducing and eliminating fugitive emissions and have created a technical solution with the design of its Oblique Cone Technology Triple Offset Butterfly Valve.

Operators are under increasing pressure to reduce fugitive emissions for both onshore and offshore assets in order to achieve their core imperatives of safe operations and minimum downtime. Severn realises the role they play in today’s climate conscious world to help reduce and eliminate fugitive emissions from valves. Utilising the engineering heritage and extensive knowledge in severe service applications, Severn ensures it can offer the most suitable product for the end user.

Through Severn’s ‘Repair Intelligence’ and close operating relationships with end user operators, Severn has been able to understand the difficulties facing operations in the specification, purchasing and servicing of Control, Choke and Butterfly valves that are critical to reducing fugitive emissions across industrial facilities. Severn prides itself in offering technical solutions that perform no matter how severe or critical the application is. Ensuring that the end user gains the best valve performance and reduced maintenance costs over the lifecycle of the valve.

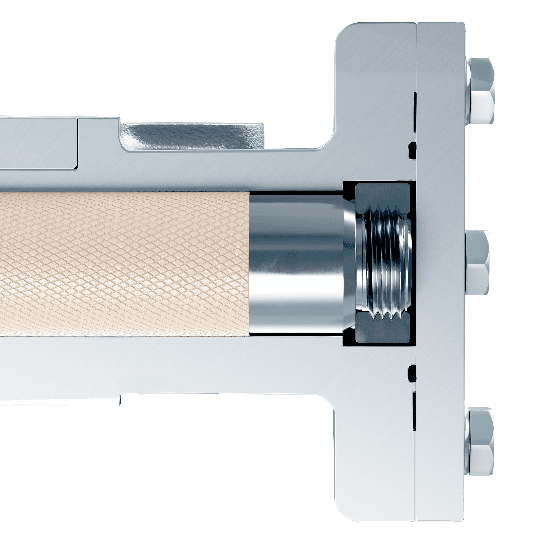

It has long been understood that approximately 60% of fugitive emissions come from valves. Even more so 80% of those emissions are related to the stem/shaft seal. Naturally, the focus is on this area with the relative fugitive emissions standards such as API 622 and ISO 15848. What is often misunderstood is the requirement for the standards to be applicable across varying temperature and pressure differentials. For this reason, Severn has 43 different certificates for sealing systems in valves based on their application requirements, up to 10,000 Psi and 425ºC. By utilising a range of materials from filled graphite through to custom PTEE-based compounds, Severn has, coupled with novel packing designs, been able to achieve tighter leakage rates that had previously been achieved with standard packing sets.

It is vital for the end user to understand the leakage class requirements when fugitive emissions are concerned to prevent over or underspecifying the solution. We often see “fugitive emissions” specified without clarification of the requirements. The various requirements from TUV through API and ISO specifications require different testing methodologies and even different testing mediums. This means that the testing standards are not directly comparable to each other. Severn often see the specification of “Low-e” or “Low emission” packing without reference to the specification. In some instances, these packing sets can have allowable leakage of up to 500ppm, many times that of systems tested to the ISO 15848-1 standard and potentially resulting in detrimental reduced on-site performance and / or higher maintenance costs.

Severn has focused and will continue to focus its testing efforts on ISO 15848 standards as it is understood that these offer the widest range of qualification options whilst not utilising harmful greenhouse gases that can be emitted using some API methodology. The fact that sealing systems are tested on the valves they are designed for and not a standard test fixture ensures maximum customer confidence in our products performance and reliability.

Severn have focused on passing some of the most stringent testing with class A leakage classes and up to 40,000 operations available for some applications. Ensuring that performance is at the heart of our product range, and you achieve your core remit of safe operations and minimum downtime.

To further the commitment to reducing fugitive emissions and reduce the burden on end users to meet tightening specifications, Severns OCT Triple Offset Butterfly Valve offers the fugitive emissions packing sets as standard fitment on all standard valves in the range. Ensuring that the end user experiences maximum valve performance in all applications.

Severn’s engineering heritage and technical expertise have led to the OCT TOV Butterfly Valve being future-proof for changes in the process conditions to provide increased versatility for the end user.

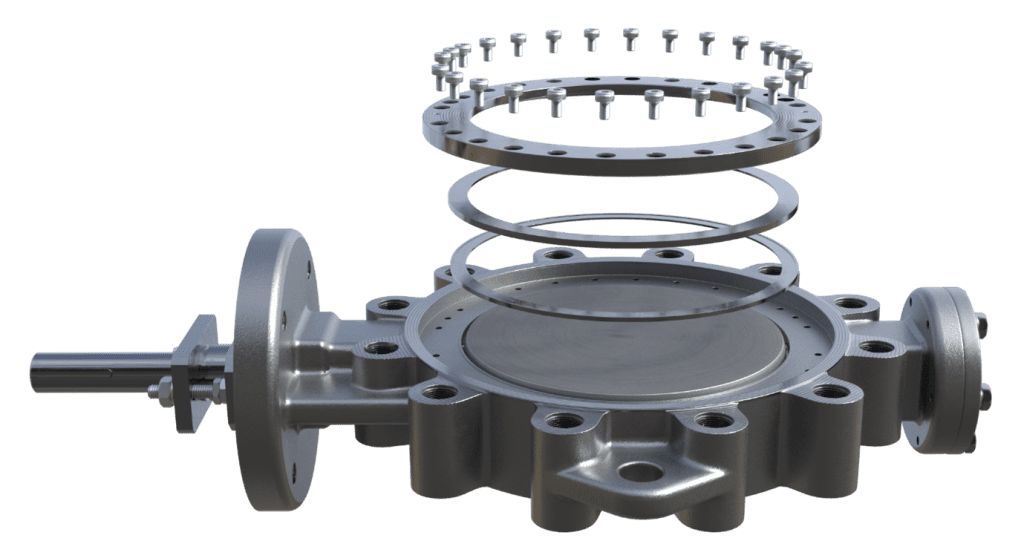

From the outset, Severn made flexibility a key driving force in the design of the Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve. Due to Severns extensive diverse engineering heritage and excellence, our expert team of engineers understand that processes and application product demands change over time, whether it is the process conditions or the overall requirements of the valve for the end user. Due to this understanding, the Oblique Cone Technology Triple Offset Butterfly Valve has been designed to incorporate multiple seal options, all fully interchangeable with each other, providing maximum application diversity and usability to ensure safe operations and minimum downtime.

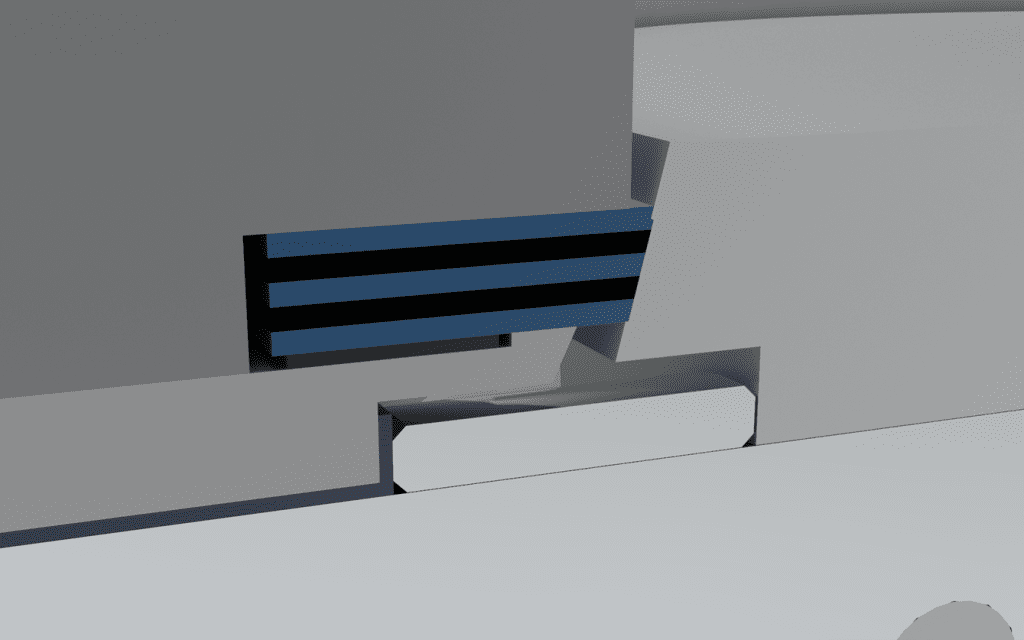

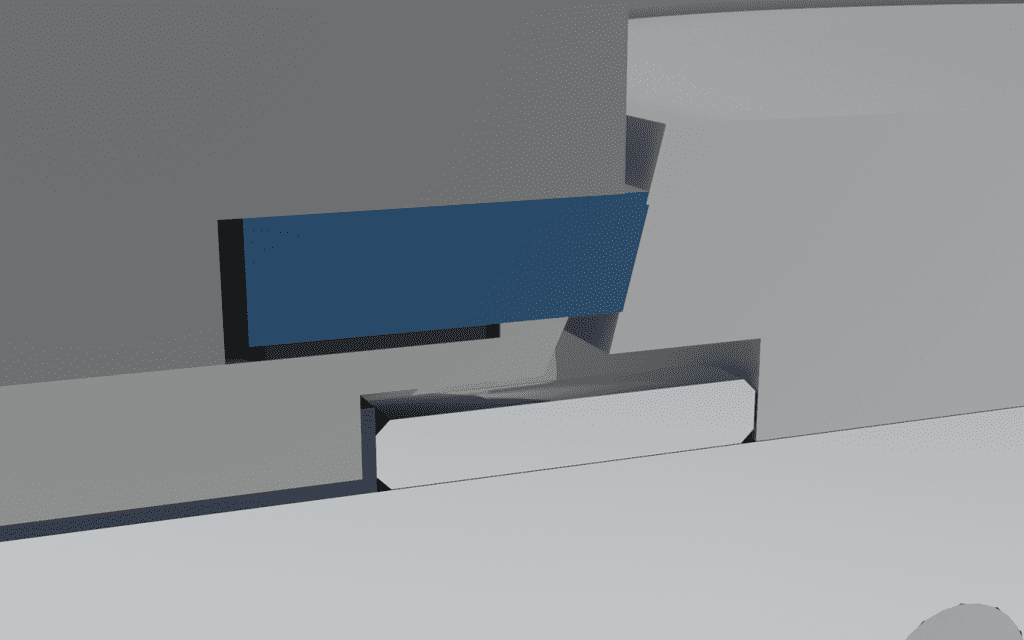

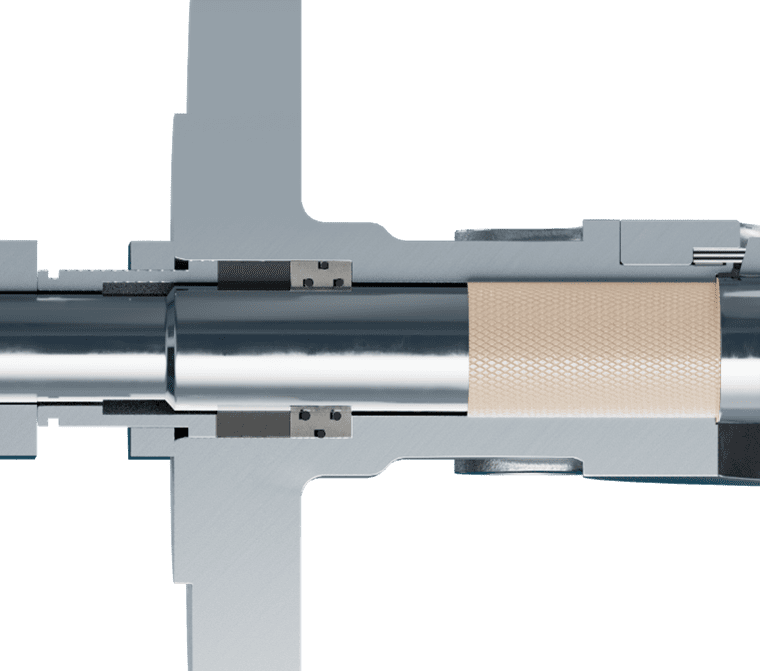

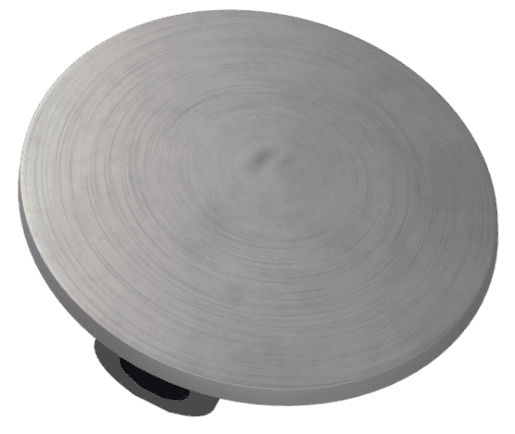

The Laminate seal is the “traditional” Triple Offset Valve seal and consists of multiple metal and graphite layers providing isolation sealing.

The OCT HS seal is a hybrid polymer metallic seal, this seal benefits from a primary metal seal and secondary polymer seal, this provides a reliable and repeatable bubble tight seal time after time. This can also be paired with PTFE packings when graphite being in contact with the line media is a concern. The polymer seal is fully compliant with EN ISO 80079-36 (ATEX).

The OCT SW Valve takes the hybrid sealing to the next level with its versatile high performance. Severn utilises the OCT-HS seal and has designed a valve that ensure there is no graphite in contact with the line media to remove the risk of costly galvanic effects such as internal corrosion leading to valve failure. Whilst doing so the OCT-SW also maintains firesafe certification.

Should the sealing requirement not become as critical, and process conditions become more arduous, the Laminate and Hybrid seals can be changed for the OCT-SS solid seal. As the name suggests it is a solid metallic seal, that can be made from hard-wearing alloys to add longevity to the sealing life of the valve in arduous conditions and can offer a control valve seat leakage.

Based on Severns comprehensive history of severe service control, our team of engineering experts work closely with operators and end uses to identify the correct seal and material selection to provide the maximum reliability and productivity further ensuring minimum downtime.

All the OCT seals are interchangeable and can be upgraded without the need for main valve components being replaced, further emphasising the OCT TOV Butterfly Valves versatility. The fully in field serviceable valve can be upgraded on-site without the need for specialist tools or knowledge, this further ensures that costly unplanned downtime and site waste is kept to a minimum, along with potential loss in production for the end user. All the seal options can be changed on site within a small space of time to ensure site maintenance costs are reduced by upgrading the existing valve rather than discarding and replacing with a commodity product each time.

Each OCT valve is specially designed to be versatile and ensure it has multiple purposes for multiple conditions whilst still delivering maximum performance. With the introduction of the interchangeable seal, these can be easily swapped out to match the end users’ requirements, should they change.

The Triple Offset Butterfly Valve Cutting Edge Design Features Leads to Comprehensive Application Coverage.

Incorporating over 60 years of engineering excellence and technical expertise in valve engineering and application, Severn offers an industry leading and patented engineering technology solution(s) for Butterfly Valve requirements and applications with the Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve. By utilising Severn’s ‘Repair Intelligence’ knowledge which involves providing real market feedback from extensive in-depth analysis from failed valves. Severn have designed each facet of the OCT TOV Butterfly Valve to provide the most accurate, reliable, and robust service capability and performance possible to help the end user achieve their core remit of safe operations and minimum downtime.

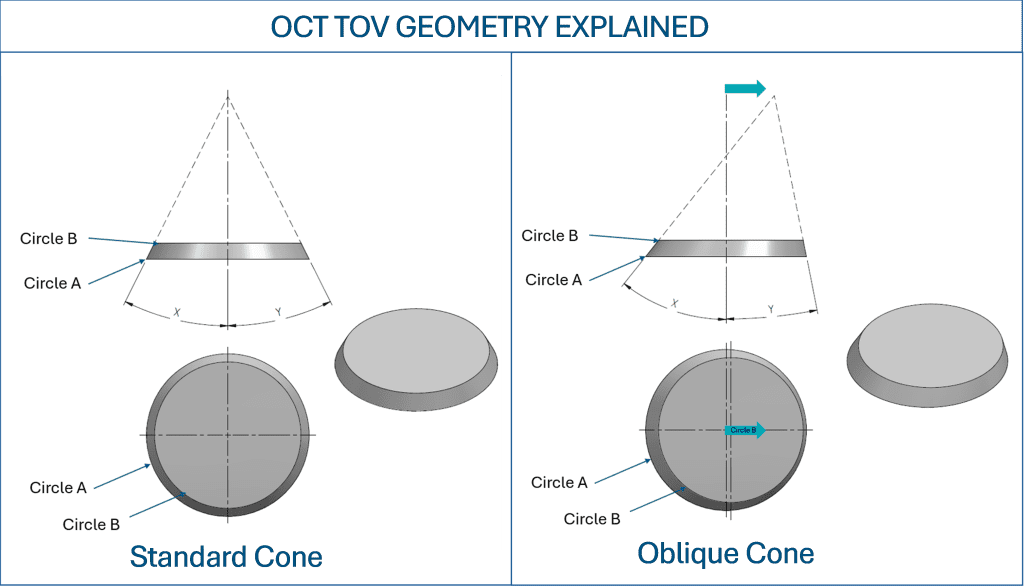

Severn’s OCT design uses circular sealing geometry, unlike traditional triple offset designs that use an ellipse. The benefit of circular geometry is that it provides a uniform sealing load around the circumference of the sealing diameter, providing a reliable and repeatable shut-off. By using circles rather than ellipses, it allows Severn to use proven circular sealing knowledge and incorporate this into the TOV Butterfly Valve.

In addition, to this we can also add specialised flow control trims that are traditionally found on double offset valves. These control trims include Anti Cavitation / Low noise, half baffle & full baffles. We can also add special features such as steam jacket and purge ports should they be required, onto our Triple Offset design.

Process conditions can change with time. Severn have ensured the interchangeability of the seal, should the sealing requirement not become as critical, or process conditions become more arduous. The HS seal can be changed to a laminated seal, or if conditions dictate, a solid seal. This can be done without the need for main valve components being replaced. The complete in-field serviceable valve can be upgraded on site without the need for specialist tools or knowledge ensuring possible down time and loss in production is kept to a minimum.

The interchangeability and versatility of the seal allows for Severn’s Triple Offset Valve to be used for both isolation and control applications and processes. The diversity of the OCT TOV Butterfly Valve and its functional usability for an extensive range of both isolation and control applications leads to the potential savings in stock holdings for end users who can use stock this one valve instead of stocking two. This in turn allows for potential cost savings for the end user on stock holding by reducing the need to stock multiple valves due to the extensive coverage that the OCT TOV Butterfly Valve offers.

Severn have designed all their Triple Offset Butterfly Valves with safety as paramount and therefore engineered the product with anti-blowout at both ends of the valve. This negates any chance of the shaft blowing out. The reduced shaft diameter at the drive end ensures the shaft cannot blow out through the packing follower and anti-blowout ring on the threaded shaft end ensures positive engagement without the need for additional fasteners.

The OCT range also comes with hard facing on the disc as standard with options to upgrade the standard hard facing to weld overlays such as stellite 6, ensuring and reliable seal and extended service life.

A quarter turn design ensures ease of actuation for both control and isolation purposes. Whether this be via an actuator or gearbox, the quarter turn design allows for simple operation.

As standard, Severn’s OCT TOV Butterfly Valve includes fugitive emission packing to ISO 15848 with options to change to meet customer specific requirements such as Shell 77/312 available.

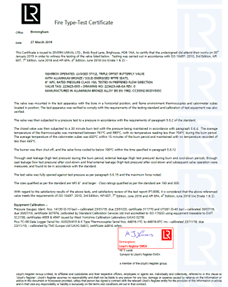

The OCT valve range has been firesafe tested & certified in accordance with the strict fire test specifications set out in the standards ISO 10497, API 607 & API 6FA. Withstanding extreme temperatures of up to 1000°C whilst still sealing. Further underpinning the performance capabilities and validating the valve performance, ensuring this valve can be suitable for an extended range of applications and process requirements, leading to safe operations and reduction unplanned downtime for the end user.

Severn offer the OCT TOV Butterfly Valve in all cast materials. From basic carbon steels to specialist alloys such as Monel, Titanium & Hastelloy. Severn can provide the correct material selection for your application. Additional surface coatings such as stellite, armoloy, chrome or weld overlays are available upon application and request.

Severn are breaking tradition with the innovative OCT Butterfly Valve and lifecycle enhancement service.

In the fast-paced industrial landscape, the emphasis on sustainability and cost-effectiveness has never been greater. Severn’s Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve is at the forefront of a new era in valve technology, where the focus shifts from immediate replacements to intelligent lifecycle enhancement and repair strategies. This paradigm shift not only promotes sustainable valve maintenance but also ensures safe operations, reduced downtime, helping you achieve your core remits.

Lifecycle Enhancement: Prolonging Valve Longevity

The traditional approach to valve maintenance often involves a “replace-first” mentality. However, Severn’s OCT TOV Butterfly Valve challenges this norm by offering a comprehensive lifecycle enhancement program. Through cutting-edge innovative engineering and materials, the OCT TOV Butterfly Valve is designed to withstand harsh operating conditions, ensuring a longer lifespan with its patented Oblique Cone Technology Triple Offset capabilities for both isolation and control applications.

By prioritizing lifecycle enhancement, industries can optimise their assets, reduce overall operational costs, and minimise the environmental footprint associated with the manufacturing and disposal of new valves.

Repair Intelligence: Smart Solutions for Complex Issues

The OCT TOV Butterfly Valve affirms the concept of Severn’s repair intelligence as the valves are designed with modular components, facilitating easy disassembly and reassembly during repairs. This not only reduces maintenance costs but also minimises the need for complete valve replacements, contributing to a more sustainable and cost-effective approach to industrial operations.

Sustainable Valve Maintenance: A Green Approach

Severn’s commitment to sustainability goes beyond the valve’s design. The OCT TOV Butterfly Valve promotes a circular economy by encouraging refurbishment and reconditioning of components. With our expert team of service engineers based globally, we can retrofit, service and repair any of our Butterfly valves on site if performance has dropped or specification or operating conditions have changed, this ensures production downtime is kept to a minimum.

Furthermore, sustainable valve maintenance aligns with global initiatives to reduce carbon emissions. By extending the life of industrial equipment, companies can decrease their carbon footprint associated with manufacturing and disposal, contributing to a greener and more environmentally responsible future.

Safe Operations and Reduced Downtime: The Ultimate Value Proposition

The OCT TOV Butterfly Valve prioritise safety through rigorous testing and compliance with industry standards such as API 598. By implementing repair intelligence and lifecycle enhancement strategies, Severn can ensure the continued reliability and safety of their valves and valve systems.

Moreover, the ability to address issues proactively minimise unexpected costly downtime. This not only enhances operational efficiency but also safeguards against potential safety hazards, ensuring a secure working environment for personnel.

Environmental Impact: A Positive Footprint for Future Generations

By choosing repair over replacement and embracing Severn’s lifecycle enhancement, industries using Severn’s OCT TOV Butterfly Valve actively contribute to reducing the environmental impact of their operations. Through sustainable valve maintenance practices, companies can align with global environmental goals, demonstrating corporate responsibility and leadership in their respective sectors.

Severn’s OCT TOV Butterfly Valve signifies a paradigm shift in the industrial valve landscape. By championing lifecycle enhancement, repair intelligence, and sustainable valve maintenance, this product offers not just cutting-edge technology but a comprehensive solution for industries seeking a balance between operational efficiency, environmental responsibility, and cost-effectiveness. In a world where every decision impacts the planet, choosing to repair, not replace, is a step towards a more sustainable and resilient future.

Fireproof Assurance: Severn’s OCT TOV Butterfly Valves Exceptional Fire Safety Design and Testing Credentials

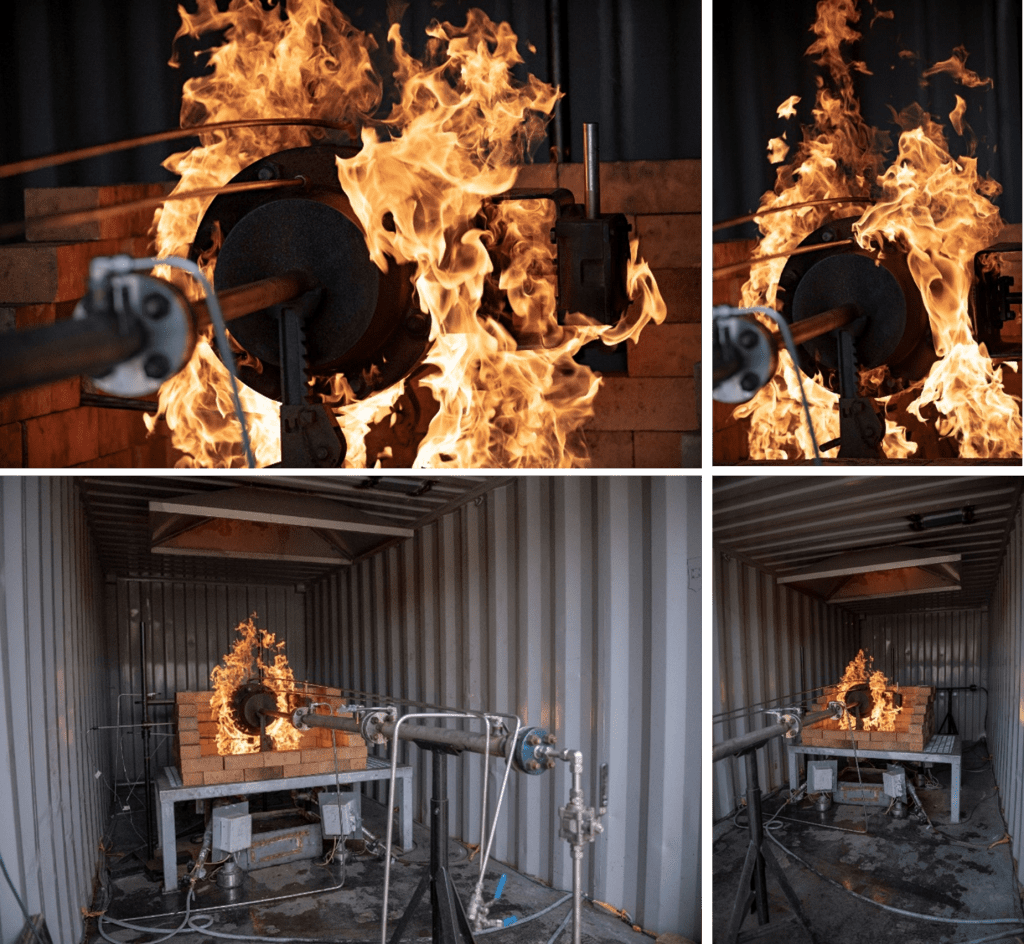

As part of a safety-first approach Severn incorporates into its innovative Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly valve, fire safety is a critical part of that safety first objective. Fire testing standards state the minimum requirements the valve must achieve in order to receive fire safe certification. The standards dictate the setup & parameters required to simulate the conditions a valve may be subjected to during a fire, and test to ensure the valve can operate satisfactorily afterwards.

To summarise, the test consists of a valve being mounted in a fire test rig to flow water through the valve, and measure leakage both internally past the seal as well as externally through the packings and gaskets. The valves are then pressure tested at ambient temperature, once the valve has passed this element of the test, any leakage is recorded. The valve is then subject to a simulated fire by use of gas burners, with average temperatures of between 750°C & 1000°C recorded by thermocouples for the 30-minute burn time. Once complete, the flames are extinguished, and the valve is subjected to a forced cooldown using water to simulate the fire being extinguished on site.

The leakage during fire is measured and recorded. The valve is then subject to a re-ambient temperature and operational test, with the maximum leakage requirements being defined within the relevant standard. The tests are carried out in both the preferred and reverse directions and are witnessed by a 3rd party approval body to give added confidence that the valve will perform as required in either flow direction.

By investing in and developing their own on-site fire test facility, Severn can understand and interpret the results to re-design & develop the fire safe valve technology for the OCT TOV Butterfly Valve, to further exceed the requirements set out in the standard. By doing this, Severn have been able to achieve up to Zero seat leakage, even after fire testing, giving further confidence to the capabilities of the valves when installed and further ensuring safety first is achieved for the end user and their operations.

The key to Severn’s success lies in their patented Oblique Cone Technology (OCT), which received approval from the UK Intellectual Property Office in 2018. This innovative design uses an ‘infinite circle’ geometry that allowed the research and development team to develop the circular sealing geometry, which gives the flexibility to use the valve for both isolation and control duties with the option of interchangeable seals and control trims.

Utilising its over 60 years of engineering heritage, Severn have designed and developed the innovative OCT TOV Butterfly Valve, a valve that meets the requirements of API 6FA, API 607, and ISO 10497 fire testing standards. These bi-directional isolation & control valves offer repeatable zero leakage, providing peace of mind for operators while ensuring safety is at the forefront.

Severn’s certification for fire test covers the OCT Laminate, Hybrid (OCT-HS) and Seawater (OCT-SW) seals, achieving the required leakage rates in accordance with the relevant international standards. By designing, developing, and testing the hybrid seal (OCT-HS) Severn have been able to understand how the hybrid polymer metallic seal acts under extreme temperatures, which has enabled them to develop a graphite free, firesafe seal, that works even after being exposed to the extremes of a fire test. By using this knowledge, the OCT-SW utilises the hybrid seal technology and prevents any graphite from contacting with the line media, therefore on seawater service eliminates galvanic effects and extends the service life of the valve.

By meeting stringent fire test standards, they have provided customers with a reliable and efficient solution to fire safety. With their patented oblique cone technology, Severn have set a new benchmark for future valve designs and innovative technology and further ensure the end user achieves its core remit of safe operations and reduced downtime.

Explore the design that has been inspired by engineering heritage and excellence to create a product that master’s isolation and control applications.

From the outset, Severn wanted the Oblique Cone Technology (OCT) to be unique in the Triple Offset valve market. Severn wanted to develop a product that not only solves an extensive range of issues for the customer with our “standard” product range, but to break tradition, and to design and manufacture a technically superior Butterfly Valve.

By utilising their comprehensive history with specialist butterfly valve design and manufacture, Severn have been able to develop a Triple Offset Butterfly Valve that performs both control and isolation duty in a single package. A valve designed from the outset to be re-used, upgraded, and provide an increased level of safety to the end user.

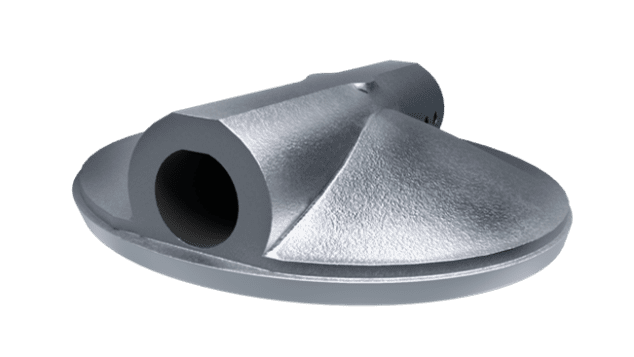

Severn have utilised its years of experience in manufacturing both the concentric and double offset Butterfly Valves to create innovative technology that pushes the boundaries of Triple Offset Butterfly Valve design. By looking at the traditional elliptical sealing concepts of Triple offset valves and combining this with circular sealing principals, Severn created its patented Oblique Cone Technology (OCT). In its most simplistic form, the geometry can be compared to a circular cone, by moving the point of the cone along one axis, this creates two different angles to the cone sides (forming an oblique cone), by taking a slice of this cone, it forms the sealing geometry of the OCT valve.

The benefit of this method means we maintain the principals of circular seals, thus providing an even seat load all-round the disc, therefore providing increased flexibility within the design to allow Severn to add different sealing options to the valve as well as specialist control trims such as anti-cavitation / low noise trims.

By understanding the foundational principals of Butterfly Valve design, Severn have a detailed knowledge of the interaction between each and every Butterfly Valve component. This combined with Severn’s Repair Intelligence philosophy and over 60 years of engineering excellence, customer solutions and end user feedback, problems can be anticipated and resolved before they occur and therefore increasing the lifecycle of the product and reducing costly unplanned downtime.

Severn additionally want to break the cycle of Butterfly Valves being a “throw away’’ commodity items. The OCT TOV Butterfly Valve is designed to be re-used, repaired, or upgraded on site with only basic tools. The robustness of the design means that the main components can be cleaned, soft goods replaced, and the valve can be reinstalled to provide extended years of reliable service. This not only reduces long term cost of ownership for the end user, but also reduces the environmental impact of the plant operations. Severn also install Fugitive Emission certified packing as standard in the OCT to further reduce the plant emission.

Flexibility and reliability come as standard in the OCT TOV Butterfly Valve. By using the principals of a Control Valve, Severn have streamlined and reduced the disc thickness to impede the flow as little as possible and maximise valve Cv. Fasteners have been removed from the disc, to eliminate the risk of them coming loose due to vibration and falling into the pipeline. The seal has also been mounted in the body rather than on the disc. This not only protects the seal by removing it from the direct flow path, but means the disc is thinner as well as giving Severn the option to add anti cavitation / low noise trims onto the disc when process conditions dictate.

The OCT principle has been installed and operating in the field for over 10 years without issues, this coupled with countless amounts of testing and validation including fire testing, pressure testing, temperature testing and cycle testing, provide the end user with confidence in the robustness and reliability of the OCT Triple Offset Butterfly valve range and ultimately minimise down time and plant costs.

With over 60 years’ experience in the design and manufacture of Butterfly Valves, Severn launches a range built on decades of learnings and innovative engineering.

In the dynamic landscape of industrial engineering, innovation often stems from a rich heritage of expertise and an unyielding commitment to excellence. Severn Glocon, a renowned name in the world of valve design and manufacturing, have once again proven this statement true with the unveiling of the superior Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve. This development represents Severn’s commitment to innovation in the realm of process and industrial energy markets, promising enhanced performance, reliability, and efficiency.

Engineering Heritage: The Foundation of Excellence

Severn’s journey to engineering eminence is woven with a tapestry of innovation and dedication stemming back over 60 years. With an engineering history extending back to 1957 and the design and manufacturing of Globe Control Valves, Severn has continuously pushed the boundaries of valve technology and design, earning a reputation for precision engineering and unmatched quality. Drawing from this extensive engineering heritage, Severn has consistently delivered solutions that exceed industry standards and address the evolving needs of diverse sectors.

Unveiling the Oblique Cone Technology (OCT)

At the heart of Severn’s latest engineering triumph lies the OCT TOV Butterfly valve, a revolutionary advancement in Butterfly valve design and performance. Unlike traditional Butterfly valves, which often suffer from limitations in sealing performance and durability, the OCT TOV Butterfly Valve introduces circular sealing geometry.

Unlike traditional triple offset designs that use an ellipse. The benefit of circular geometry is that it provides a uniform sealing load around the circumference of the sealing diameter, providing a reliable and repeatable shut-off. By using circles rather than ellipses, it allows Severn to use proven circular sealing knowledge and incorporate this into the TOV.

Incorporating Severn’s ‘Repair Intelligence’ knowledge which involves providing real market feedback from extensive in-depth analysis from failed valves. Severn have designed each facet of this valve to provide the most accurate, reliable, and robust service capability possible whether managing critical processes in Oil & Gas refineries, Chemical Plants, or Power Generation facilities, the OCT TOV Butterfly valve ensures the end user achieves their core remit of safe operations and minimum downtime.

Advantages for Process and Industrial Energy Markets

The introduction of the innovative OCT TOV Butterfly Valve designed by Severn signifies a paradigm shift in valve technology, offering a host of benefits to the Process & Industrial Energy markets

Enhanced Performance: Severn have designed each facet of this valve to provide the most accurate, reliable, and robust service capability possible to help the end user achieve their core remit of safe operations and minimum downtime.

Extended Lifecycle: Process conditions can change with time. Severn have ensured the interchangeability of the seal, should the sealing requirement not become as critical, or process conditions become more arduous.

Increased Safety: At Severn, safety is paramount to the design of our products and ensured that whilst adhering to the strictest industry standards, have incorporated shaft blowout prevention as a vital addition to the design of the valve to increase suitability for end users and the wider industry.

Versatility: Utilising Severn’s extended history of engineering excellence, the OCT TOV Butterfly valve has been designed for both superior control in both throttling and modulating services, whilst additionally providing a repeatable seal for isolation duties.

Environmental Sustainability: To further the commitment to reducing fugitive emissions and reduce the burden on end users to meet tightening specifications, all Severn’s OCT triple offset butterfly range offer the fugitive emissions packing sets as standard fitment on all standard valves in the range.

Severn’s relentless pursuit of engineering excellence has culminated in the development of the OCT Triple Offset Butterfly Valve – a testament to the company’s unwavering commitment to innovation and customer satisfaction. As industries worldwide seek ever-improving solutions to their operational challenges, Severn Glocon stands ready to lead the way, setting new benchmarks for performance, reliability, and efficiency in valve technology.

Severn makes ice-road deadline.

An ice-road waits for no one, so Brighouse engineers had their work cut out ensuring six butterfly valves were ready to reach a north Russian LNG plant before the spring melt.

The order comprised four 20” ASME 300 and two 16” ASME 900 double flanged short pattern triple offset butterfly valves.

To ensure Severn makes the ice-road deadline, the Brighouse team designed, manufactured, assembled and tested the valves in-house, comfortably shipping them by the mid-March deadline.

Manufactured in CF8M with electric actuators, these control valves surpassed the customer’s Class IV leakage requirement, achieving the more challenging ‘Class VI or better’ standard.

Severn manufactures and supports high quality valves for the energy industries. Its control, choke and small bore subsea valves are pre-eminent in the global market, underpinning the reliability and high performance of business-critical client infrastructure.

Severn’s global reach, technical prowess, and collaborative approach – all founded upon a heritage of British engineering excellence – help to assure production continuity for clients and reduce the prospect of costly downtime.

Its understanding of the life-cycle of assets positions Severn to offer end-to-end engineering solutions, enabling clients to meet their core imperatives: safe operations and minimum downtime.