Severn Solve Severe Service Water Injection Issues with High Performance Flow Control Valve

Posted: 18 August 2022Severn were approached at a external technology event, to assist in engineering a solution for a Onshore Oil & Gas client based in the MEA region that was having severe issues with multi-stage trim Flow Control valves failing after only a matter of weeks installation.

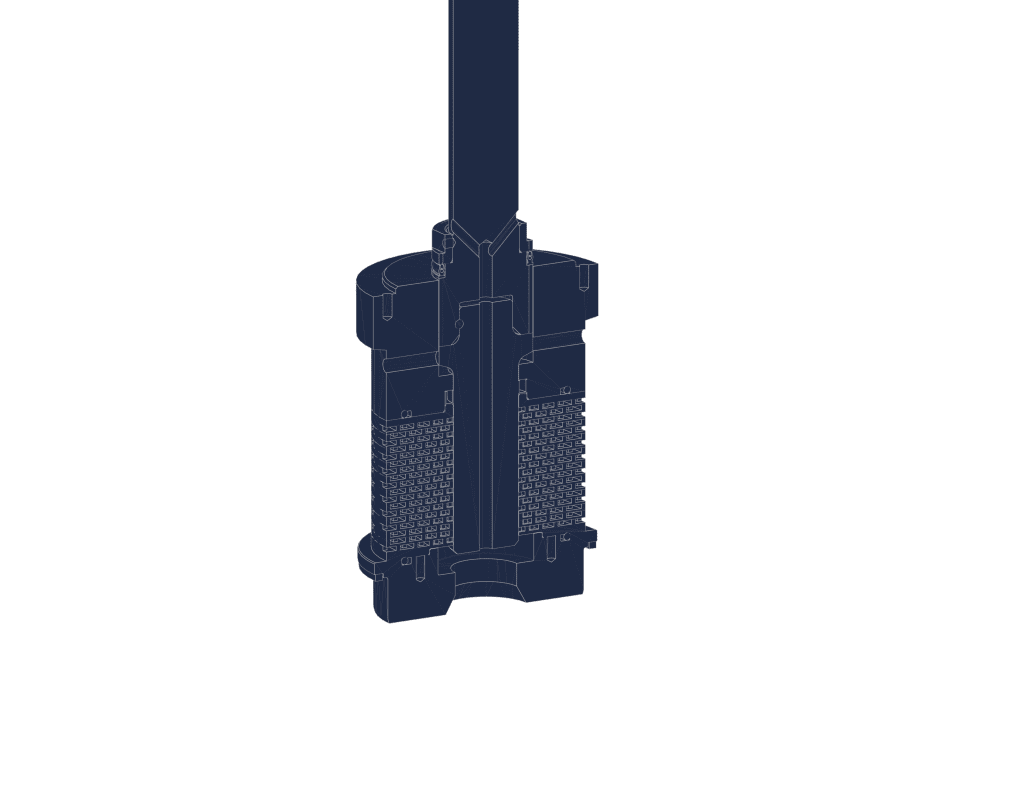

The images to the right are of one of the competitors multi-stage trim Flow Control valves that had failed after a few weeks of installation. As you can see the level of erosion and cavitation is extremely severe and highlighted how demanding the application was due to dealing with fluids such as formation water, produced water, saline, sand, and dissolved gas flowing through the valve.

Identifying the Challenges

After extensive conversations with the client, it was agreed that Severn would provide a high-performance Flow Control valve for this bespoke application issue. One of the initial challenges set by the client was the challenging acceptance criteria for what would pass as success or failure for the valves performance.

Download the case study in full below:

More News

All News- Posted: 22 July 2024 Severn’s OCT TOV Butterfly Valve Exceeds Fire Safety Testing

- Posted: 15 July 2024 Severn’s OCT TOV Butterfly Valve Goes Beyond Meeting Safety Accreditation

- Posted: 8 July 2024 Exploring Cavitation and Its Impact on Valves

- Posted: 1 July 2024 Control or Isolation – Why Are They Different?

- Posted: 24 June 2024 Understanding the Innovative Oblique Cone Technology in Severn’s OCT TOV Butterfly Valve

- Posted: 17 June 2024 Severn Combines Engineering Excellence and Heritage to Develop a Superior Butterfly Valve Range.