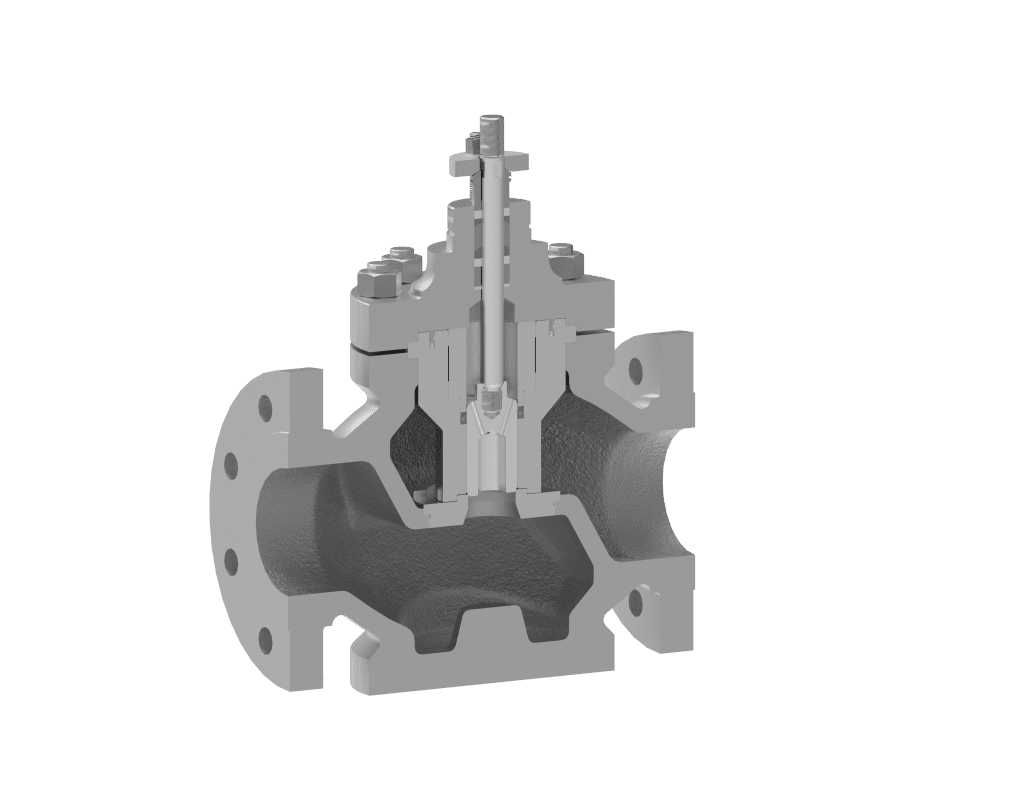

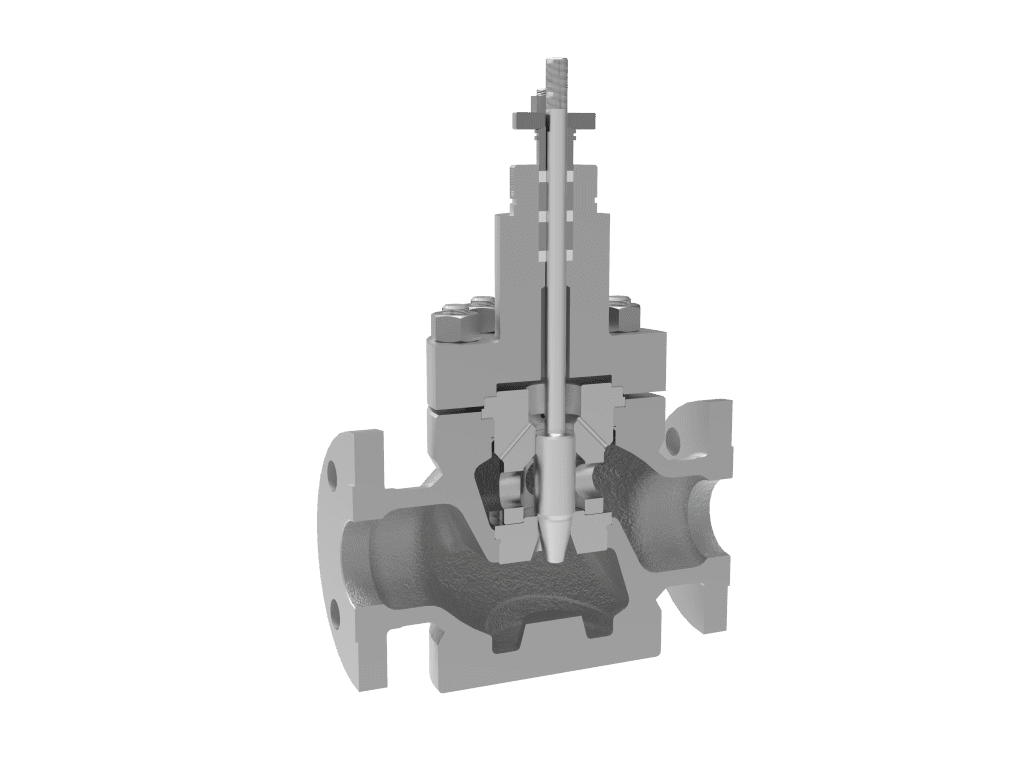

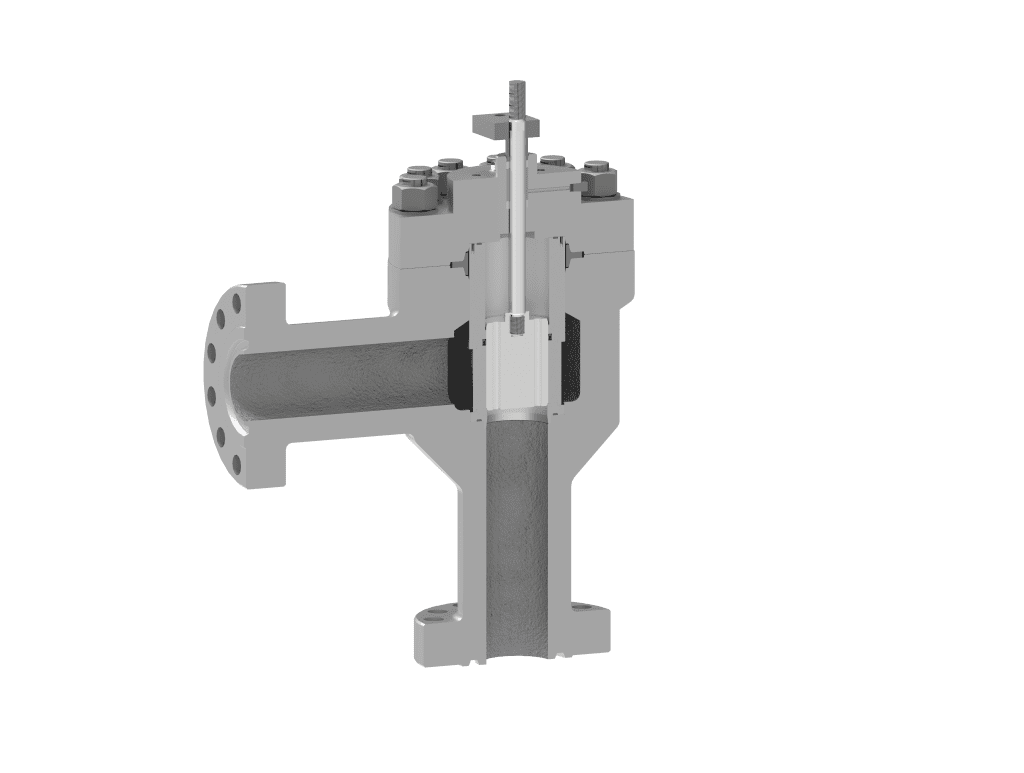

The Severn 1000 Series Severe Service Control Valve benefits from more than five decades of experience in providing cost effective and easily maintained valves for applications found through the applications of Power and Oil and Gas Industries.

The simple design provides rugged reliability and is based upon a cast top entry style body in a range of material options. The 1000 Series Control Valve is available with a screwed seat through to advanced multi-stage trim options.

Design Features:

- Smooth profile cast globe body construction

- Wide range of trim options available

- Robust part for trouble free service and low cost of ownership

- Valve body proportioned to withstand high pipe stresses without distortion

- Inherently characterised trims available in linear, equal percentage or semi-throttle

- Both balanced and unbalanced trim designs available with soft seat or hardened insert option

Benefits:

- Top-entry servicing with immediate access to plug and seat

- Reduced inspection and maintenance costs

- Trims compact and easy to install

- Excellent flow capacity and control rangeability

- Reduces potential erosion and noise problems

- Reliable leakage performance, bubble tight shut off available

- Low actuating forces required with balanced trim styles

To find out more about the 1000 Series Control Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

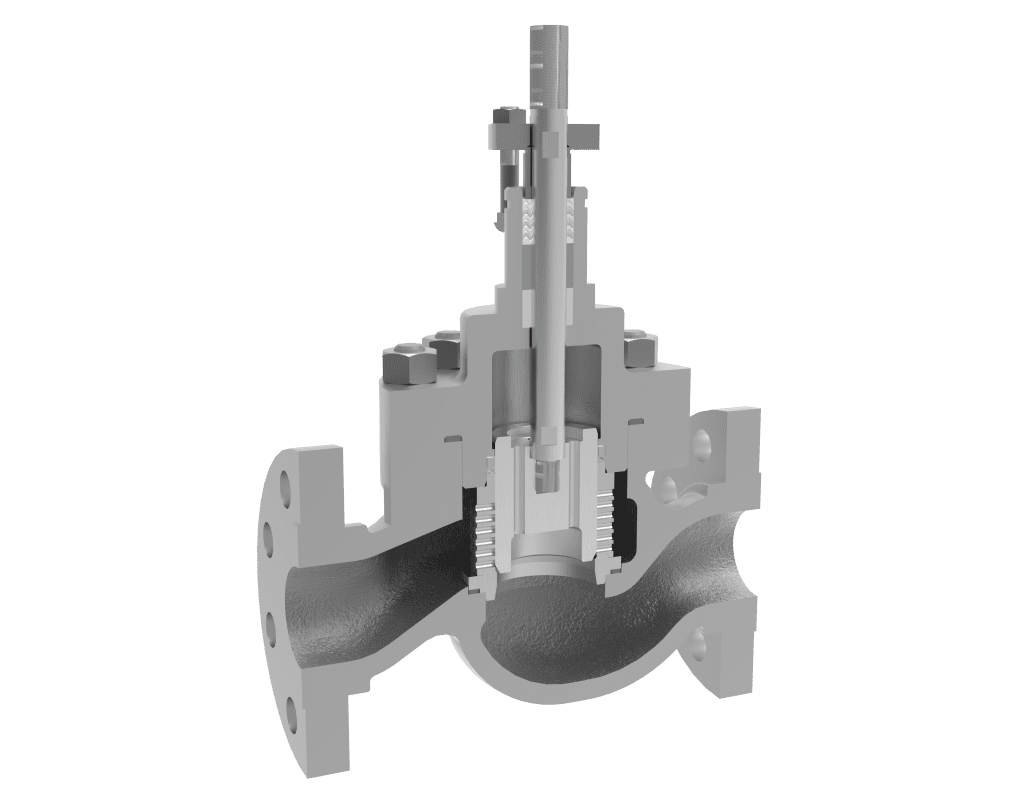

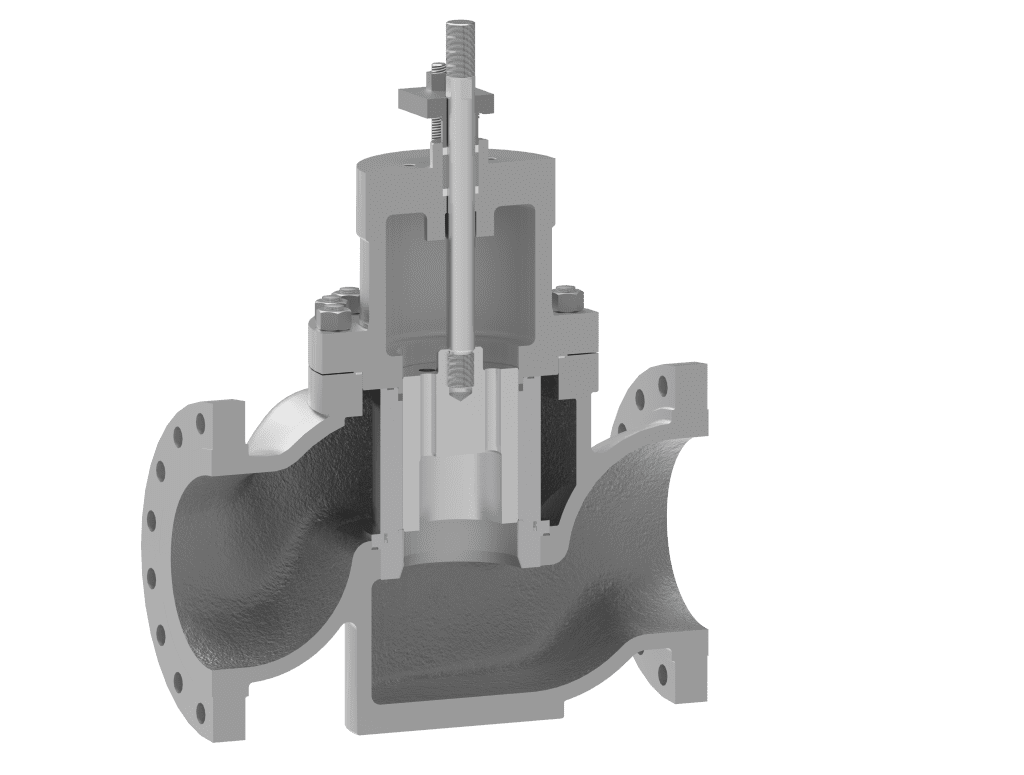

The 1200P Series Globe Control Valve is designed to exceed the expectations of hydrocarbon and similar industry applications.

The hallmarks of the 1200P design are its high flow capacity, durable shut-off and low emission performance. The 1200P Series also uses NACE conforming material options to provide reduced overall dimensions and weights for increased valve performance.

The unique static balance seal with camped seat, minimised use of shims / gaskets. Along with robust cage guiding ensures ruggedness and durability.

Standardised components and interchangeability and interchangeability across sizes, ratings and trim options enable less inventory and spares, paving the way for stock holding and shorter lead times. The 1200P series is designed for ease in manufacturing, assembly, operation, and maintenance.

Design Features:

- Smooth profile cast globe and angle body construction

- Quick-change trim as standard

- Micro spline, contoured, 1CC and 2CC trim options

- Robust parts for trouble free service and low maintenance costs

- Inherently characterised trims available in linear, bi-linear or equal percentage

- Substantial guiding

- Wide choice of packing systems including low fugitive emission designs

- Integral plug system construction option

- Both balanced and unbalanced trim designs with soft seat insert options

Benefits

- Top-entry servicing with easily maintained trim sets

- Reduced inspection and maintenance costs

- Trims are easily installed

- High flow capacity and control rangeability

- Reliable leakage performance. Bubble tight shut off available

- High interchangeability between sizes and other products

- Low weight

- Manufactured to ISO 29001 certification and compliant with PED requirements

- Low actuating forces required with balanced trim styles

To find out more about the 1200P Series Control Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

The 1200 Series Globe Control Valve is designed to exceed the expectations of Hydrocarbon and similar industry applications. Higher flow capacity, durable shut-off, low emission, NACE conforming material options, reduced overall dimension and weight are the hallmarks of this design.

The static balance seal with clamped seal, minimised use of shims / gaskets along with robust cage guiding ensures ruggedness and durability.

Standardised components and interchangeability across sizes, ratings and trim options enable less inventory and spares, paving way for stock holding and shorter lead times. The product is designed for ease in manufacturing, assembly, operation, and maintenance.

Design Features:

- Smooth profile cast globe and angle body construction

- Quick-change trim as standard

- Micro spline, contoured, 1CC and 2CC trim options

- Robust parts for trouble free service and low maintenance costs

- Inherently characterised trims available in linear, bi-linear or equal percentage

- Substantial guiding

- Wide choice of packing systems including low fugitive emission designs

- Integral plug system construction option

- Both balanced and unbalanced trim designs with soft seat insert options

Benefits:

- Top-entry servicing with easily maintained trim sets

- Reduced inspection and maintenance costs

- Trims are easily installed

- High flow capacity and control rangeability

- Reliable leakage performance. Bubble tight shut off available

- High interchangeability between sizes and other products

- Low weight

- Manufactured to ISO 29001 certification and compliant with PED requirements

- Low actuating forces required with balanced trim styles

To find out more about the 1200 Series Control valve, download the brochure via the downloads section on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

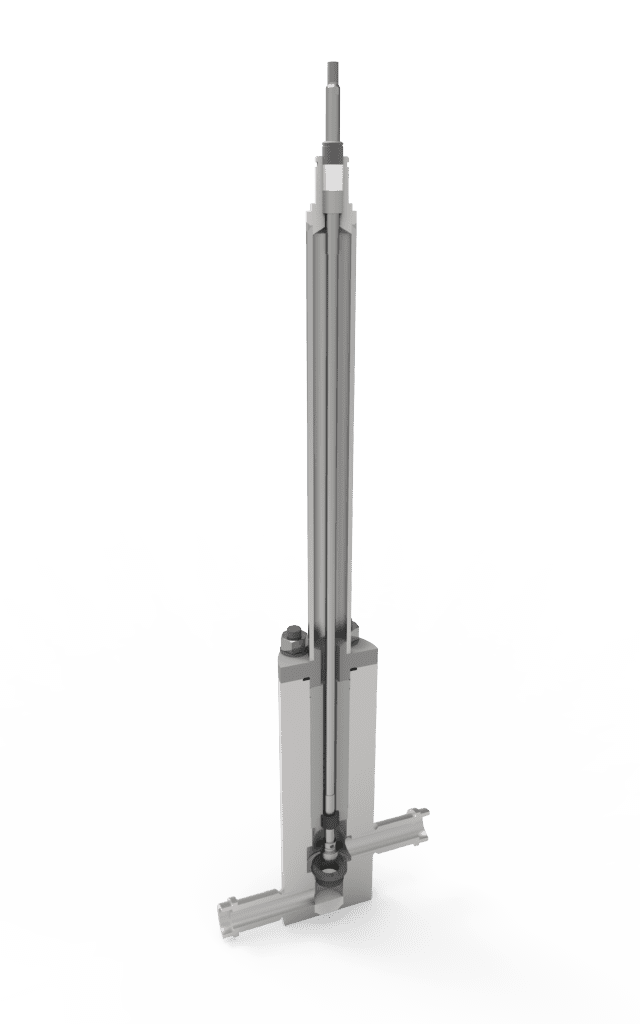

The Severn 3000 Series Control Valve was initially developed over five decades specifically for installation in cryogenic cold boxes. As such, the 3000 Series now benefits from extensive experience in providing cost effective and easily maintained valves in an industry which makes stringent demands upon its suppliers.

Construction materials of the body are generally aluminium or stainless steel to suit adjoining pipework, while the fully machined flow path minimises particle pick up and ensures a degree of cleanliness necessary for the industrial gas market.

Design Features:

- Smooth profile barstock globe, angle, and three-way body construction

- Extension & body lengths to suit installation

- Cold box flange adjustable or welded

- Clamped or screwed in seat standard, cage trim options

- Large choice of trim sizes available with low noise and anti-cavitation options

- Robust parts for trouble free service and low cost of ownership

- Inherently characterised trims available in linear, equal percentage or semi-throttle

- Cleaned and degreased for Oxygen service as required

- Soft seat insert option for ANSI Class VI shutoff

- Various options of weld end and flanged connections

Benefits

- Top-entry service with direct access to plug and seat reducing inspection and maintenance costs

- Extensive trim selection

- Excellent flow capacity and control rangeability

- Reliable leakage performance, bubble tight shut off available

- High interchangeability between sizes and other products

- X-ray option available on all welds

To find out more about the 3000 Series Control Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

The Severn 4000 series was initially developed over two decades ago specifically to satisfy the installation in cryogenic ASU and Hyco cold boxes of an all welded in construction, thus prevent any possibility of leakage within the insulated area, while giving full access to the valve trim from outside the cold box.

As such the 4000 Series Control Valve now benefits from extensive experience in providing cost effective and easily maintained valves in an industry which makes stringent demands from its suppliers.

Construction materials of the body is either stainless steel (model 4400) or aluminium (model 4300) to suit adjoining pipework. Internal surface finish is considered to be of major importance to ensure degrees of cleanliness that are necessary for the Industrial Gas market and therefore all valves are cleaned and assembled suitable for oxygen service as standard.

Design Features:

- Model 4400 – one piece stainless steel body / extension

- Model 4300 – aluminium body / stainless steel extension factory assembled

- Smooth profile globe body construction

- Extension lengths to suit installation

- Cold box flange adjustable or welded

- Screwed in seat standard, cartridge cage trim options

- Large choice of trim sizes available with low noise and anti-cavitation options

- Robust parts for trouble free service and low cost of ownership

- Inherently characterised trims available in linear equal percentage or semi-throttle

- Cleaned and degreased for Oxygen service as standard

- Soft seat insert option for ANSI Class VI

- Various options of end connection

Benefits

- Top-entry servicing with direct access to plug and seat

- Reduced inspection and maintenance costs

- Extensive trim selection

- Reliable leakage performance, bubble tight shut off available

- High interchangeability between sizes and other products

- X-ray option available on all welds

To find out more about the 4000 Series Control Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

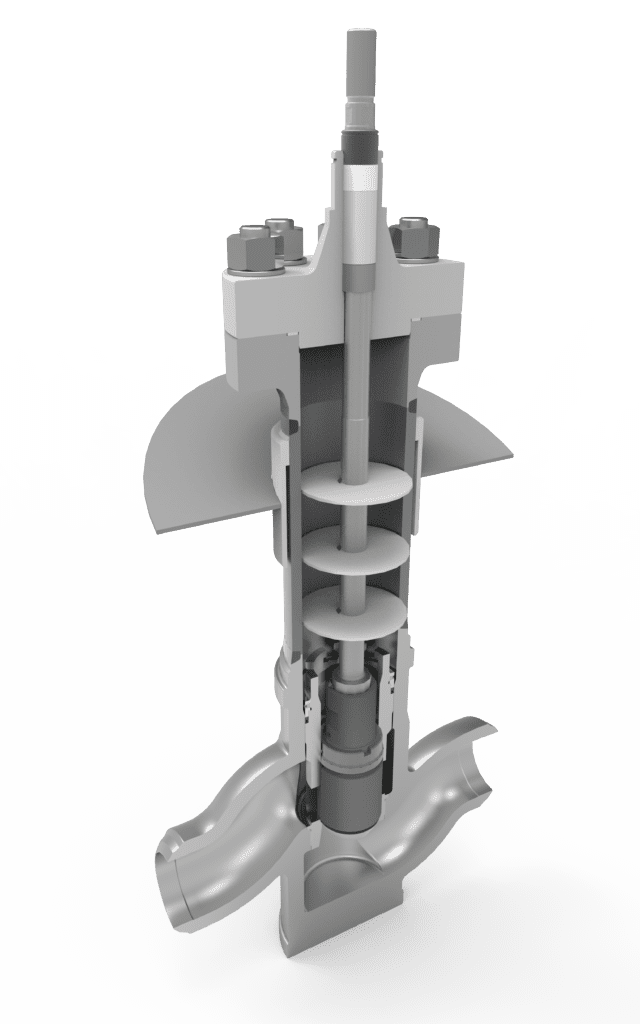

The 5000 Series range of Globe Control Valves benefits from more than 40 years of infield experience to deliver high performance, easily maintained, reliable and high-quality valves for the most severe applications.

The wide choice of materials used for manufacture offers bespoke application solutions, while the smooth body flow path reduces turbulence, minimising the effects of erosion and noise.

Design Features:

- Smooth profile cast globe, angle and three-way body construction

- Quick-change trim as standard

- Wide choice of trim sizes available with low noise and anti-cavitation options

- Robust parts for trouble free service and low maintenance costs

- Inherently characterised trims available in linear, bi-linear, equal percentage or semi-throttle

- Substantial guiding

- Wide choice of packing systems including low fugitive emission designs

- Integral plug system construction option

- Both balanced and unbalanced trim designs with soft seat insert options

Benefits

- Top-entry servicing with easily maintained trim sets

- Reduced inspection and maintenance costs

- Trims are easily installed

- Excellent flow capacity and control rangeability

- Design reduces potential erosion and noise issues

- High interchangeability between sizes and other products

- Rigorous in-field testing

- Manufactured to ISO 29001 certification and compliant with PED requirements

- Low actuating forces required with balanced trim styles

The quick-change trim option allows easily accessible trim components to minimise fitting and replacement times.

Stem-guided contoured trim in both balanced and unbalanced configuration gives excellent rigidity and resistance to vibration and service wear. The valve is designed to accommodate other products within the Severn range, for example, MLT, CC low noise, and anti-cavitation trims.

The vast array of repair intelligence has been utilised to develop the most robust method of design. The 5000 Series utilises the latest trim technology from the simple contoured plug through to the multi-labyrinth trims, paving the way for future upgrades if required. The robust guiding of the 5000 Series valves provides excellent rigidity to vibration regardless of the valves configuration, meaning increased service intervals and reduced downtime.

To find out more about the 5000 Series Control Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

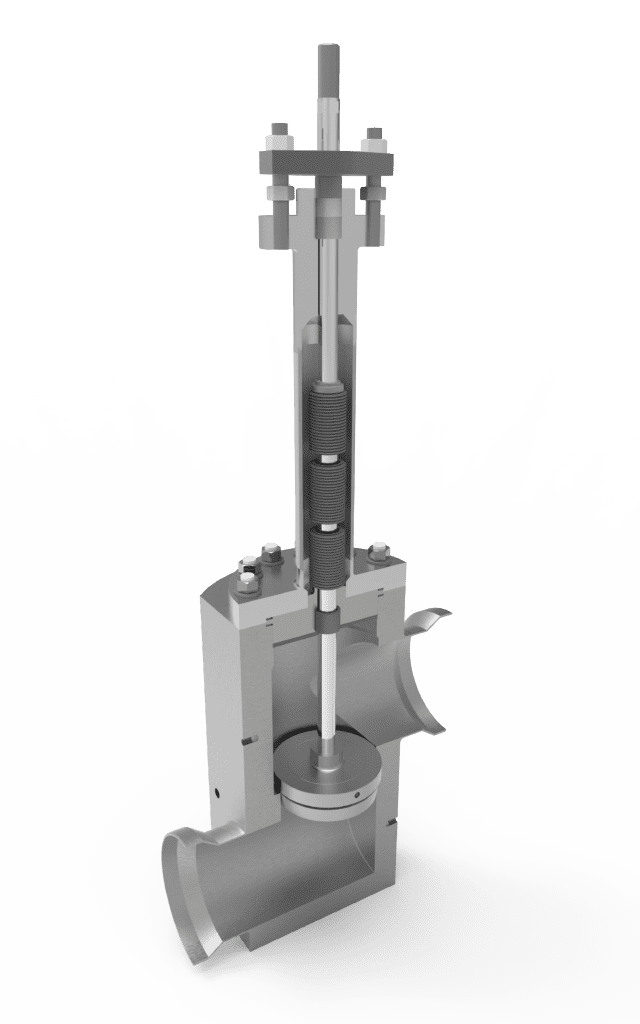

Severn is recognised by major oil and gas operators as a global specialist in the design, manufacture and supply of severe service Control and Choke valves. The 5200 Choke Valve Series has been designed to offer a robust and viable solution to customer’s needs. This series includes both API and ASME designs.

The 5200 Series choke range delivers reliable control of production rates from the wellhead to the production header.

The choke, designed to deal with initial high pressure at well start-up, is used to balance production rates in the production header – both in terms of best production fluid make-up as well as optimisation of the individual well operation and pressure.

The range is especially designed to control fluid velocity through effective multi-stage pressure reduction. Combined with the effective use of erosion-resistant materials and optimum fluid impingement angles, the modular choke valve offers superior lifetime performance to the end user.

Design Features:

- API monogram if required

- Rigid construction of body ensures structural integrity

- Top opening design for each trim removal / servicing

- Design allows interchangeability of trim parts and trim upgrade

- Large metal seal ring design allows safe and reliable disassembly / assembly of valve for maintenance

- Balanced or unbalanced designs

- Safety features like pressure relief mechanism & anti blow-out design

- Customised yoke option allows reduced valve heights

- High integrity low fugitive emission gland packing available

- Multiple trim options from fixed orifice to multi labyrinth trims

To find out more about the 5200 Series Choke Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

The Severn 7000 Series was initially developed specifically for installations in cryogenic and warm service Ultra High Purity Systems for the semi conduction industry. As such, the 7000 Series now benefits from extensive experience in providing cost effective and easily maintained valves in an industry that makes very stringent design demands upon its suppliers.

Compact installation has always been a major consideration in Severn designs and therefore Z angle styles are favoured over large Y pattern bodies. Construction materials of the body are generally forged 316L stainless steel to suit connecting pipework, while the fully machined crevice free flow path minimises particle pick up and ensures the degree of cleanliness necessary for this sector of the Industrial Gas market.

Design Features:

- Smooth profile crevice free body construction

- High-capacity body

- Electronic Grade surface finish options

- Large choice of trim sizes

- Robust parts for trouble free service and low cost of ownership

- Inherently characterised trims available in linear, equal percentage and semi throttle

- Bellows designed specifically for modulating service

- Soft seat insert option for ANSI Class VI

- Various options of weld end connections

- Perpendicular actuator orientation

Benefits:

- Top entry servicing with direct access to plug assembly

- Reliable leakage performance, bubble tight shut off available

- X-ray options on welds

- Interchangeability between other Severn products

To find out more about the 7000 Series Control Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.

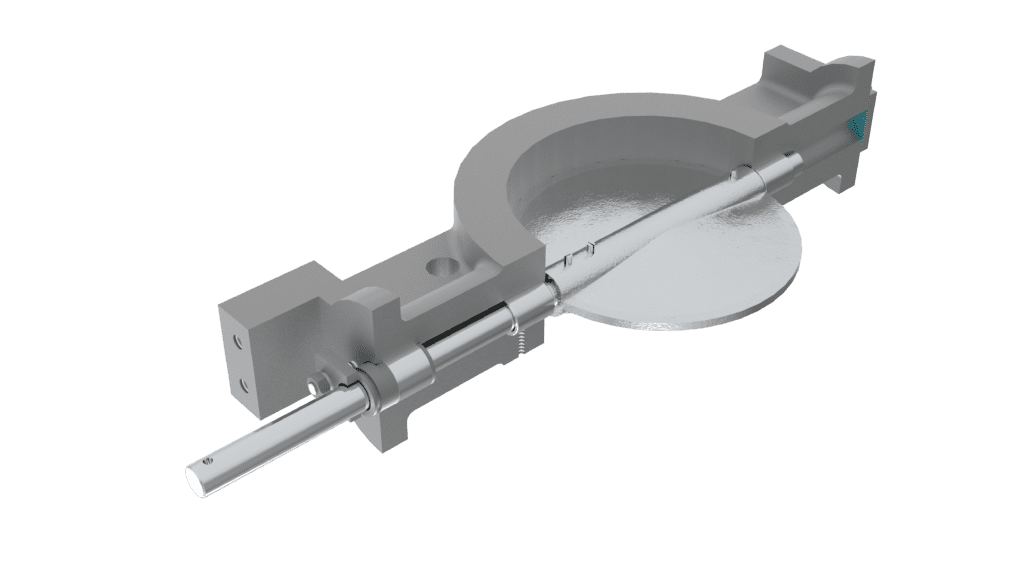

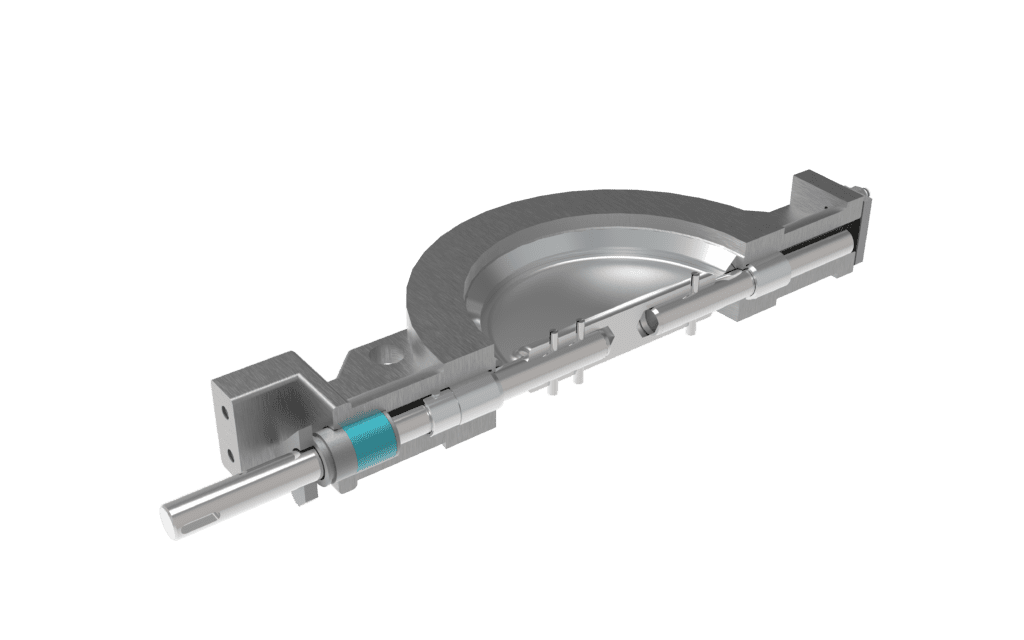

The Severn Swing Clear and Step Seat Butterfly Valves are designed to control the flow of liquids and gases for more severe service applications typically encountered in chemical and petrochemical applications where a complete tight shut-off is not essential.

Severn’s types of Swing Clear and Step Seat valve bodies include Wafer, Lugged, Double Flanged and Butt Weld Ends. The discs have a streamlined shape which provides minimum resistance to flow and on large valve ribs, are incorporated for extra strength. Special clearance is provided between body and disc to prevent seizure in valves used at elevated temperatures.

Design Features:

- Designed to control the flow of liquids and gases for more severe applications generally encountered in a chemical and petrochemical applications where a complete tight shut-off is not essential

- The ‘Swing Clear’ disc which has no contact with the valve body enables the valves to be used with high pressures and a wide range of temperatures

- Reduced leakage can be obtained with our Step Seat valves on limited applications, high and low temperature gasses

- Sizes from 2in (50mm) up to 88in (2200mm)

- Streamlined shape disc which provides minimum resistance to flow and on larger valves ribs are incorporated for extra strength

- Standard pattern valves are generally designed to suit a static maximum pressure up to 10 bar and pressure differentials depending on valve size and construction

- Temperature ranges of up to -190°C up to 1000°C

Benefits

- Low torque

- Maximised Cv

- Hard facing options available for improved abrasion resistance

- Available with a range of low noise and anti-cavitation trims

- Reliable performance

To find out more about the 8100-8200 Butterfly Valve, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.