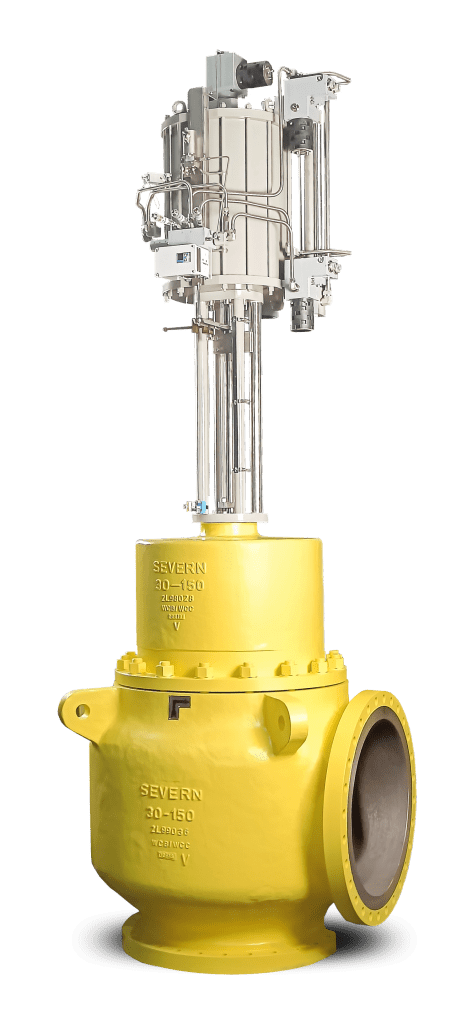

The 5000 Series range of Anti-Surge valves benefits from decades of infield experience to deliver high performance, easily maintained, reliable and high-quality valves for the most severe applications.

The high-capacity body galleries ensure maximum capacity and valve performance.

The high tun down trims provide the required controllability for high value Anti-Surge applications while ensuring the capacity requirements of 1.8-2.2 times the maximum capacities are adhered to, ensuring reliability and precision for the end user.

- High-capacity globe and angle bodies

- Quick change trim as standard

- Robust parts for trouble free service and low maintenance costs

- Inherently characterised trims available in linear, bi-linear, equal percentage

- Substantial guiding

- Wide choice of packing systems including low fugitive emission designs to ISO 15848-1

- High performance, high force actuators

- Superior accuracy

- High performance meeting industry specifications without concession

Sizes

- 1/2in (12mm) – 42in (900mm). Integral or Separable Flanges, Screwed, Butt or Socket weld ends. For other styles please contact us.

Valve Body Ratings

- ASME 150 – 4500

- EN 1092 PN 10 to PN 400

- API 5000 – API 15000

Body Styles

- Globe

- Angle

End Connections

- Raised Face.

- Flat Face.

- Ring Type Joint.

- Butt Weld End available on request.

Bonnet Styles

- Standard.

- High temperature.

- Cryogenic.

Trim options

- Concentric Cage(s), Multi-labyrinth trim and Varstage. A vast array of alternative trims are available depending on the application.

Construction Materials

- A wide range of standard materials are available for both the valve pressure containing parts and trim, including carbon and stainless steel, duplex/super duplex and high nickel alloys. Stellite, and other hard facings/coatings are available. We also provide a range of tungsten carbide and ceramic material options for severe service trims. For further details on materials please contact us.

Actuation

- High power double acting piston actuators

Instruments

- A wide range of control instruments are available from Severn, including: positioners, air-filter regulators, volume boosters, solenoid valves, and lock-up valves.

- How Highly Engineered Compressor Surge Control Improves LNG Plant Performance – Coming Soon

- How to Boost the Durability and Functionality of LNG Compressor Anti-Surge Valves – Coming Soon

- LNG compressor problems? – Coming Soon

- Severn’s Anti-Surge Valves Satisfy Rigours of Dynamic Testing, Without Concession – Coming Soon

- HIPPS – Coming Soon

- LNG Industry – Coming Soon

For 60 years, Severn’s focus has been upon maximising the performance of its products to help clients secure their safety and commercial objectives. We have a long history of providing Anti-Surge Actuator valves and actuator systems for the most demanding of Anti-Surge applications.

Specific Anti-Surge standards are extremely strict and difficult to achieve. However, through significant investment and extensive R&D, Severn has achieved the following:

- The Compressor Controls Corporation (CCC) AN17 specification

- The Nuovo Pignone (GE) specification

Severn’s experience in satisfying many challenging compressor Anti-Surge applications has shown that bespoke design is the key to achieving optimum performance. Each application is uniquely sized, selected and designed in line with the client’s specific requirements to offer unparalleled reliability and value.

- Extremely fast acting

- Rapid response and accurate positioning

- Consistent performance

- Optimized for valve travels and shutoff conditions

- Low friction seals

- Sealed from external contaminants

- Robustly guided

Medium & High-Pressure Air Filters remove moisture, oil, vapours, odours, carbon monoxide and other gaseous vapours and solid particulates commonly present in ordinary compressed air.

Deployment of our Medium & High-Pressure Air Filters results in high quality, clean air suitable for breathing applications. They conform to BS EN 12021 and DEF STAN 68/284 standards, we can also achieve other standards upon request.

The filters are constructed of carbon steel or stainless steel. The filter head can be unscrewed by hand and all filter parts can be renewed in minutes without the use of tools. All units can also be provided with manual drain valves.

Adsorption Filters are available as three, four or five stage systems and normally comprising a glass microfiber coalescer filter.

Our Adsorption Filters are manufactured to remove liquid oil from the compressed air stream with an activated carbon, desiccant and/or catalytic canister to remove water and hydrocarbon vapour and odours, and/or to reduce carbon monoxide concentrations. They also have an in-line filter for final removal of dust particles.

Regenerative Desiccant Dryers deliver a high level of customised engineering combined with highly skilled small batch manufacture.

At Bentley, we have spent over 40 years developing these capabilities to serve the small and specialist market for High Pressure Regenerative Desiccant Dryers.

Our dryers are frequently packaged together with up to six stages of pre and after filtration (of our own manufacture) to meet the highest standards of air/gas quality. They are built to give many years of reliable and safe operation under the most demanding working conditions.

They are used extensively for many applications. These include defence standard ‘pure air’ for thermal imaging, medical and special gases, air blast circuit breakers, ships’ systems, waveguide dryers and dockside services.

Particulate (Dust) Filters are are fitted with elements of various grades to remove and prevent the carry-over of dust or other particles – to 0.01 micron and above.

The capabilities of our Particulate (Dust) Filters make them ideal as an after-filter for desiccant dryers or for applications where a high standard of filtration is required.

The filter element is constructed of pleated layers of glass fibres in an in-depth arrangement, which can accumulate large amounts of solid particles and resist clogging. This allows a gradual increase in pressure drop across the filter, resulting in a long operational life.

Pre-Filters feature a mechanical 1 micron separator element to remove heavy condensates.

Our Pre-Filters also have the ability to retain large quantities of solid particles without clogging.

Water/Oil Demister Filters incorporate unique cartridges for silencing and separating water/oil mist from low and high pressure compressed air exhaust drainage points.

Our solutions remove 100% of water/oil mist particles from air being exhausted at pressures up to 6,500psig (450 bar g) to atmosphere. They also eliminate water/oil mist and smoke within buildings and ensure a clean working atmosphere.

The filters can be installed inside or outside buildings, allow the use of compressed air drainage points where environmental regulations would not normally allow (especially new industrial estates), and provide suitable collection points for waste disposal.

They have been designed for compressed air systems where it is necessary to silence, separate and collect all condensate and sludge discharge from air compressor inter-cooler stages – including after cooler, air dryers, air receivers, filters and automatic drain traps. They are ideal for areas where cleanliness is important and where site water/oil condensate and sludge cannot be sent directly to drains or wasted over a floor area. Their special cartridges combine excellent liquid separation characteristics with fine filtration and a large capacity for containment of liquid condensate.

Our Oil Demister Filter vessels are constructed of carbon steel and are available with either a large removable top lid to allow air to be exhausted direct to atmosphere, or a flanged pipeline unit with bottom swing bolt closure for applications where the exhaust has to be piped to a suitable discharge point.